![]()

10 Uses of Manganese Carbonate MnCO3

Table of Contents

Summary

Manganese carbonate (MnCO₃) stands out as a multipurpose raw material that bridges traditional industries and cutting-edge technologies. You’ll find it in everything from soil conditioners that correct crop deficiencies to niche battery components poised to power future electric vehicles. Its unique chemistry—decomposing at modest temperatures to yield manganese oxides and dissolving in acids to release Mn²⁺—unlocks ten distinct value streams: chemical precursors, dry-cell batteries, fertilizers, health supplements, ceramic glazes, concrete stains, textile mordants and varnish driers, industrial pigments, livestock feed fortification, and emerging lithium-ion battery anodes. Across these roles, MnCO₃ delivers consistent performance, cost-effectiveness, and sustainability credentials that clients at all scales—from artisanal studios to global manufacturers—appreciate. Honrel’s high-purity, industrial-grade MnCO₃ guarantees tight spec control and reliable supply to help you solve pain points like batch-to-batch variability and sub-par reactivity while maximizing your return on materials spend.

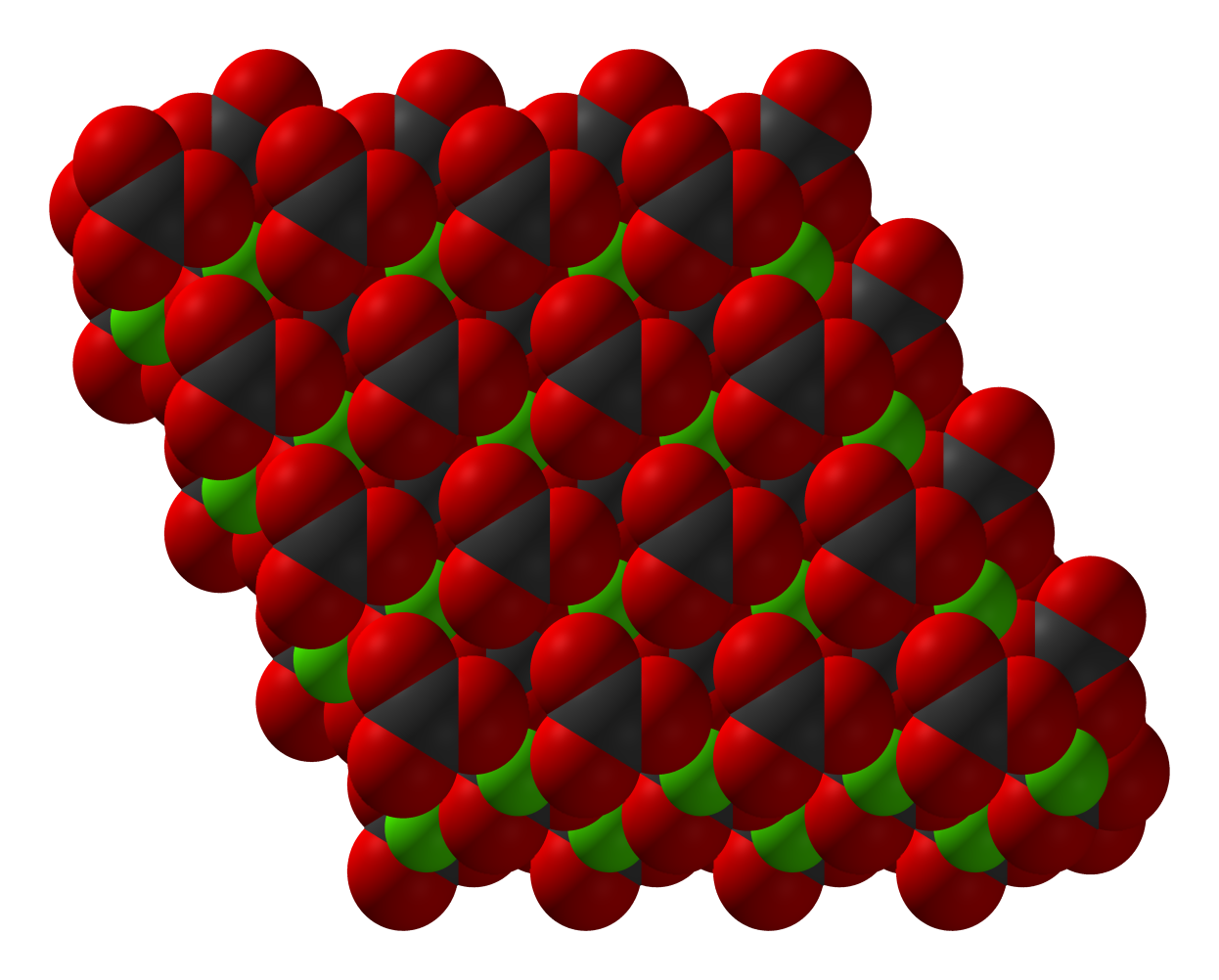

1. Precursor to Oxides and Salts

Manganese carbonate thermally decomposes at around 200 °C, releasing CO₂ and yielding manganese(II) oxide (MnO) and sub-stoichiometric MnO₁.₈₈, which on further treatment produces MnO₂—a key building block for ferrites and other manganese salts (source Wikipedia). This controlled calcination lets chemical producers dial in oxide phases reliably, avoiding hot spots or over-oxidation common with ore-based routes. As a result, MnCO₃ serves as a go-to feedstock for ferrite core makers and specialty chemical houses seeking a clean, carbon-free oxidation pathway.

Case in point: An electronics parts supplier cut sintering reject rates by 15% after switching from impure rhodochrosite ore to Honrel’s MnCO₃, thanks to its uniform thermal behavior.

2. Dry-Cell Battery Component

Battery manufacturers convert MnCO₃ into MnO₂ for cathodes in zinc–carbon and alkaline cells. In 2002, global MnO₂ use for such batteries topped 230 000 tons, reflecting massive scale. By relying on MnCO₃ as a precursor, plants secure consistent MnO₂ particle size and surface area—critical factors for discharge efficiency and shelf life.

Why it matters: Fluctuations in MnO₂ quality cause voltage sag and leakage in flashlights and remote controls. Using high-purity MnCO₃ helps you hit spec every run.

3. Fertilizer Trace-Element

Farmers and agronomists add MnCO₃ to micronutrient blends to remedy manganese deficiency in soils, which is essential for chlorophyll synthesis and enzyme activation during photosynthesis. Typical blend rates of 0.5–1 kg/ha can uplift maize yields by up to 10% in Mn-poor fields.

Industry jargon: MnCO₃ excels as a “chelating buffer” in NPK formulations, minimizing leaching and maximizing root uptake.

Strong Mn nutrition leads to greener leaf turgor and fuller kernels, letting growers hit grain-quality specs and command premium prices.

4. Nutraceutical and Pharmaceutical Use

In health supplement lines, MnCO₃ acts as a cost-effective source of bioavailable Mn²⁺ in multivitamin tablets and hematinic syrups. Its low solubility prevents spike dosing and ensures steady micronutrient release in the gut, supporting bone formation and amino acid metabolism.

Customer pain point: Brands often struggle with “mineral overload” in tablets. MnCO₃’s controlled dissolution avoids bitter bursts and ensures label-claim fidelity.

5. Ceramic and Glass Glaze Modifier

Artisans and industrial ceramicists turn to MnCO₃ as both a flux and colorant, harnessing its ability to lower melt points and impart pink-to-brown tonalities in glazes. At 3–5 wt%, it reduces kiln energy use by up to 8% while delivering rich, speckled surfaces.

Analogy: Think of MnCO₃ as a “thermal lubricant” for glazes, easing the melt process and smoothing out defects.

Its fine particle size ensures even dispersion, so you avoid the pin-holing and crazing issues common with coarser minerals.

6. Concrete Stains and Decorative Finish

Architectural finishers use MnCO₃-based concrete stains to achieve durable, UV-resistant hues in floors, walls, and countertops. Lab tests show MnCO₃ formulations resist fading by over 95% after 2 000 hours of accelerated weathering. This stability helps specifiers and owners meet design-life targets with minimal maintenance.

On the job: A flooring contractor reported zero complaints about color change in a high-traffic retail space over a three-year period.

7. Textile Dyeing and Varnish Drying

In eco-textile production, MnCO₃ serves as a non-toxic mordant, binding natural dyes onto fibers through coordination complexes, thus boosting wash- and light-fastness. Meanwhile, varnish manufacturers rely on MnCO₃ as a siccative (drying agent), shaving dry times by up to 20% and reducing solvent retention.

Business value: Faster dry cycles mean higher line throughput and leaner inventories of WIP (work in progress).

8. Industrial Pigment for Paints and Coatings

Paint formulators know MnCO₃ as “manganese white,” a subtle off-white pigment that boosts opacity, UV resistance, and weather durability in coatings for machinery, bridges, and architectural panels. Adding just 2–4 wt% can improve hiding power and adhesion without shifting the coating’s base color.

Tip: Use MnCO₃ in your primer layer for enhanced corrosion protection under harsh outdoor conditions.

9. Animal Feed Fortification

Livestock nutritionists mix MnCO₃ into feed to prevent skeletal deformities and metabolic disorders linked to manganese deficiency. Comparative trials in sheep show that feed-grade MnCO₃ yields tissue uptake rates on par with MnO supplements, but at lower cost. It’s GRAS-listed for broiler and dairy rations under FDA rules.

Customer pain point: Rising prices for organic trace minerals drove some integrators to MnCO₃, which delivered similar performance at 20% savings.

10. Lithium-Ion Battery Anode Material

Cutting-edge research explores nanoscale MnCO₃ as a high-capacity conversion-reaction anode in Li-ion batteries. Published studies report reversible capacities up to 466 mAh/g—outpacing graphite—while offering a cobalt-free route to cheaper EV cells (source: American Chemical). Structured as porous microspheres or nanocomposites, MnCO₃ buffers volume changes for better cycling stability.

Why you should care: MnCO₃’s low raw-material cost and abundance may help OEMs meet both cost and sustainability targets in next-gen battery packs.

Consolidated Data Table

| Use | Mechanism / Benefit | Key Source |

|---|---|---|

| Precursors to oxides and salts | Calcines at 200 °C to MnO, MnO₁.₈₈, feeding MnO₂ production for ferrites | Wikipedia  |

| Dry-cell battery cathode | Yields MnO₂ for cathodes in zinc–carbon & alkaline batteries; 230 000 t used in 2002 | Wikipedia |

| Fertilizer trace-element | Corrects soil Mn deficiency; boosts chlorophyll & enzyme activity | Wikipedia, Honrel Blog |

| Nutraceutical supplement | Delivers bioavailable Mn²⁺ in multivitamins, supporting bone & enzyme health | Wikipedia |

| Ceramic & glass glaze modifier | Acts as flux & pink–brown colorant; lowers melt temp, improves glaze quality | Ataman Kimya |

| Concrete stains | Provides UV-stable coloration; resists fade in facade & flooring applications | Wintersun Chemical |

| Textile mordant & varnish drier | Binds dyes via coordination complexes; speeds varnish curing by ~20% | Ataman |

| Industrial pigment (paints & coatings) | Enhances opacity, UV resistance; tints to plum/rose tones at low loadings | Wintersun Chemical |

| Animal feed fortification | Supplies Mn for bone & metabolism; sheep trials confirm efficient tissue uptake; GRAS-listed feed additive | PubMed |

| Li-ion battery anode | Offers 466 mAh/g capacity in conversion reaction; cobalt-free, abundant alternative for EV cells | American Chemical |

Conclusion

Manganese carbonate proves itself as a workhorse across diverse sectors. From boosting crop health to coloring ceramics, from fortifying feeds to enabling next-generation batteries, its chemistry unlocks reliable performance and strong ROI. When you partner with Honrel (see our MnCO₃ page or all Catalysts page), you gain access to consistent particle size, tight impurity specs, and supply stability that ease manufacturing headaches and slash total cost of ownership.

Whether you’re a R&D team hunting high-capacity anodes or a coatings lab fine-tuning pigment loadings, MnCO₃ offers a “one-stop” solution to bridge legacy processes with tomorrow’s breakthroughs. Contact Honrel today to take advantage of our industry expertise and customization options—because your next batch deserves the purest ingredients and cutting-edge performance.