![]()

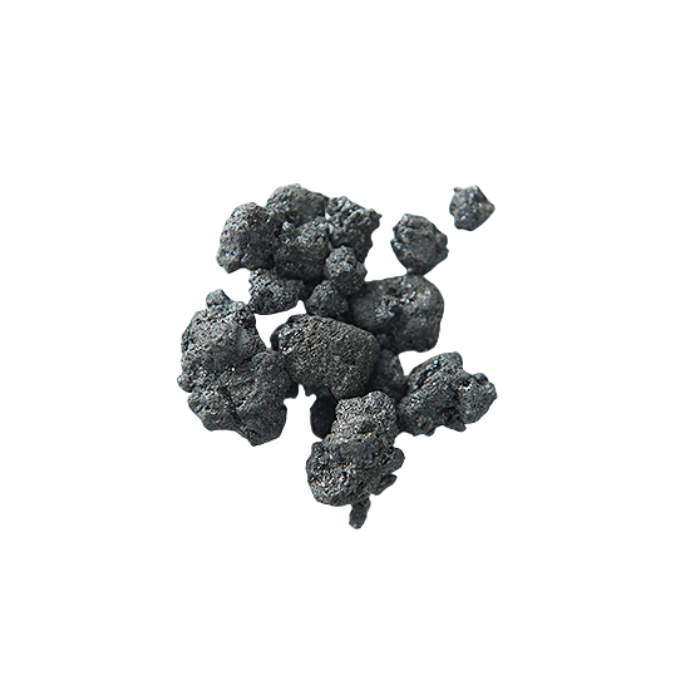

Abrasive White Fused Alumina

Abrasive White Fused Alumina: A Comprehensive Guide to Its Uses and Applications

Abrasive white fused alumina is a highly versatile, synthetic abrasive material that plays an essential role across various industries. Known for its exceptional hardness, high purity, and outstanding wear resistance, abrasive white fused alumina is a preferred choice for manufacturing abrasive products and other high-performance materials. This article will explore the multiple applications, benefits, and characteristics of abrasive white fused alumina, shedding light on why it is one of the most popular abrasives in the world.

Table of Contents

1. What is Abrasive White Fused Alumina?

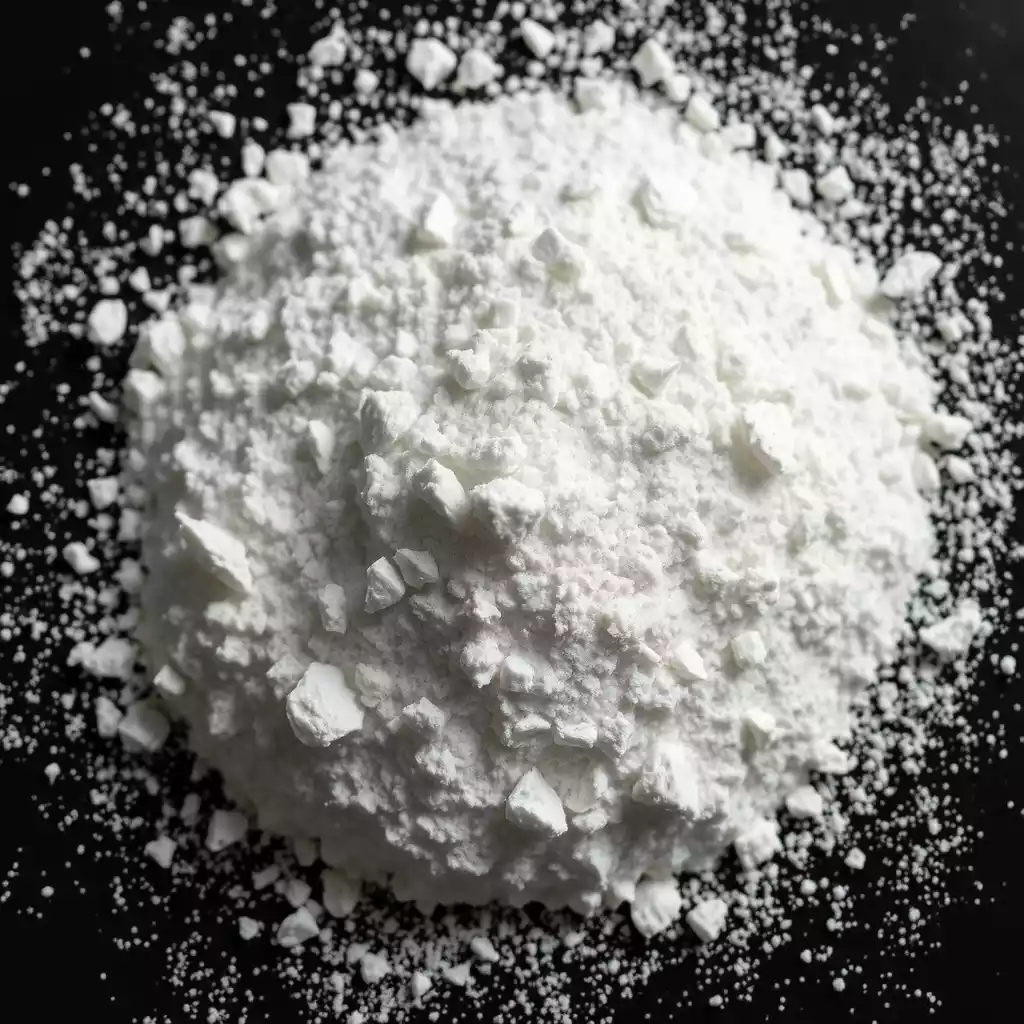

Abrasive white fused alumina (WFA) is a high-purity aluminum oxide material derived from the fusion of bauxite in an electric arc furnace. With its crystal-clear, white color, WFA is created through the controlled process of heating alumina to temperatures exceeding 2000°C. This process results in a material that is extremely hard, making it ideal for applications that demand durability and wear resistance.

White fused alumina is a synthetic material with applications spanning across abrasive products, refractories, and more. Its hardness and high resistance to chemical reactions make it a sought-after choice for industries such as metalworking, automotive, electronics, and environmental management.

Discover more about abrasive materials.

2. Characteristics of Abrasive White Fused Alumina

Abrasive white fused alumina stands out for several unique properties that make it suitable for a wide range of industrial applications:

- Hardness: With a Mohs hardness of 9, abrasive white fused alumina is extremely hard, just below diamond. This characteristic makes it ideal for cutting, grinding, and polishing applications.

- Purity: White fused alumina boasts a high purity (typically greater than 99% Al₂O₃), ensuring minimal contamination during abrasive processes.

- Chemical Stability: WFA is chemically inert, meaning it does not react with most acids and bases, making it highly durable in harsh environments.

- Thermal Resistance: White fused alumina can withstand high temperatures, making it ideal for refractory and casting applications.

- Low Dusting: The low dusting property makes it easier to handle, reducing health risks and environmental impact during abrasive blasting and other operations.

Learn about the benefits of white fused alumina.

3. Abrasive Applications of White Fused Alumina

Abrasive white fused alumina is primarily used in the production of abrasives, where its hardness and durability shine. Some key applications in this category include:

Grinding and Polishing

White fused alumina is an essential ingredient in the production of grinding wheels, polishing compounds, and abrasive pastes. It is commonly used for grinding metals, ceramics, and composite materials, as well as polishing delicate surfaces in the semiconductor, jewelry, and automotive industries.

Blasting Media

Abrasive white fused alumina is widely used in sandblasting and shot blasting operations for surface cleaning and preparation. It is particularly effective for removing coatings, rust, and contaminants from metal surfaces without causing damage. Its angular particles provide aggressive cleaning action, making it perfect for high-performance sandblasting applications.

Explore white fused alumina for sandblasting.

Abrasive Paper and Pads

WFA is also used in the manufacture of abrasive papers, pads, and cloths, ideal for sanding and polishing wood, metal, and plastic surfaces. Its sharp, crystalline structure ensures efficient material removal while minimizing wear on the abrasive tool.

4. Refractory Applications of White Fused Alumina

Abrasive white fused alumina is not only used in abrasive applications but is also a crucial material in the production of refractories due to its high melting point, thermal stability, and chemical resistance. Some of the key refractory uses include:

- Kiln and Furnace Linings: WFA is used for manufacturing bricks and linings for high-temperature industrial furnaces, kilns, and reactors.

- Refractory Castables: White fused alumina is employed in castable refractories that are used in steelmaking and other high-temperature operations.

- Thermal Insulation: Due to its low thermal conductivity, WFA is also used in insulation materials that are exposed to high temperatures.

For high-performance refractory solutions, visit Honrel’s refractory materials page.

5. Industrial Uses of White Fused Alumina

In addition to abrasive and refractory applications, white fused alumina is used in several other industries:

Environmental Applications

White fused alumina is used in water and air filtration systems due to its porosity and high surface area. It helps to remove contaminants and improve the quality of water, air, and other environmental media.

Catalyst Supports

Its chemical inertness and stability at high temperatures make abrasive white fused alumina an ideal material for use as a support for catalysts in various chemical processes, such as in the petrochemical industry.

Ceramic Manufacturing

White fused alumina is often used in the production of advanced ceramics and electronic components, where its hardness, high purity, and thermal stability are crucial.

Explore our full range of chemical raw materials.

6. Advantages of Using Abrasive White Fused Alumina

When considering abrasive white fused alumina for industrial applications, several advantages make it stand out:

- Long-lasting Performance: Due to its high hardness, WFA abrasives last longer than other abrasive materials, which helps reduce operational costs.

- Consistency: White fused alumina is produced under controlled conditions, ensuring consistency in size, purity, and performance across batches.

- Environmentally Friendly: WFA is a sustainable material that can be recycled and used in various applications without environmental harm.

- Safety: Compared to other abrasive materials, WFA produces less dust and is less likely to cause respiratory issues, improving safety in industrial settings.

7. White Fused Alumina vs. Other Abrasive Materials

White fused alumina is often compared to other abrasive materials such as brown fused alumina, silicon carbide, and zirconia. Here’s a quick comparison:

| Feature | White Fused Alumina | Brown Fused Alumina | Silicon Carbide | Zirconia |

|---|---|---|---|---|

| Hardness | 9 on the Mohs scale | 8-9 on the Mohs scale | 9-9.5 on the Mohs scale | 8 on the Mohs scale |

| Purity | 99% Al₂O₃ or higher | ~95% Al₂O₃ | ~99% SiC | ~95% ZrO₂ |

| Applications | Precision abrasives, refractories | General abrasives, shot blasting | Harder abrasive, cutting tool | Heavy-duty abrasives, grinding |

| Cost | Higher due to purity | Lower cost due to impurities | Higher cost due to composition | Higher cost for high performance |

White fused alumina is ideal for high-precision and high-purity applications, while brown fused alumina is typically more affordable for general abrasive use.

8. Sourcing Quality Abrasive White Fused Alumina

To ensure high-quality abrasive white fused alumina, it’s essential to source from trusted suppliers who specialize in premium-grade materials. At Honrel, we offer high-purity white fused alumina that meets the stringent requirements of various industrial applications. Whether you’re manufacturing abrasive products, refractories, or catalyst supports, our white fused alumina provides the performance you need for success.

9. Future Trends in Abrasive White Fused Alumina

The demand for abrasive white fused alumina is expected to grow, driven by advancements in precision manufacturing, aerospace, automotive, and environmental technologies. As industries evolve, the need for higher-performing, sustainable materials like WFA will continue to increase.

New applications for white fused alumina, particularly in energy storage and battery technologies, are also emerging, making it a material to watch in the coming years.

10. Frequently Asked Questions (FAQs)

1. What is abrasive white fused alumina used for?

Abrasive white fused alumina is used primarily in abrasives, grinding wheels, sandblasting, polishing compounds, and as a refractory material.

2. How is white fused alumina produced?

White fused alumina is produced by melting alumina (Al₂O₃) in an electric arc furnace at temperatures exceeding 2000°C.

3. What makes white fused alumina better than other abrasives?

Its high purity, hardness, and chemical stability make white fused alumina superior for precision and high-performance applications.

4. Can white fused alumina be recycled?

Yes, white fused alumina can be recycled and reused in various industrial processes.

5. Is white fused alumina safe to handle?

Yes, it is considered safe to handle, especially compared to other abrasives that produce harmful dust.

6. What industries use abrasive white fused alumina?

It is used in industries such as automotive, aerospace, metalworking, environmental management, and ceramics.

7. How does white fused alumina compare to brown fused alumina?

White fused alumina is purer and harder, making it suitable for precision work, while brown fused alumina is used for general abrasive purposes.

8. Where can I purchase high-quality white fused alumina?

You can purchase premium white fused alumina from reliable suppliers like Honrel.

Conclusion

Abrasive white fused alumina is a material with unmatched versatility and performance. Its exceptional hardness, purity, and resistance to high temperatures make it the ideal choice for a wide range of applications, from abrasives and refractories to environmental and industrial uses. By sourcing high-quality white fused alumina from trusted suppliers like Honrel, businesses can ensure that they are using the best material for their applications, leading to better results and long-term cost savings.