![]()

Ammonium Molybdate Tetrahydrate Supplier Ultra Purity

Ammonium Molybdate Tetrahydrate Supplier: Why Ultra-Purity Defines Modern Industry

Table of Contents

1. AMT’s Role in Tech-Driven Industries

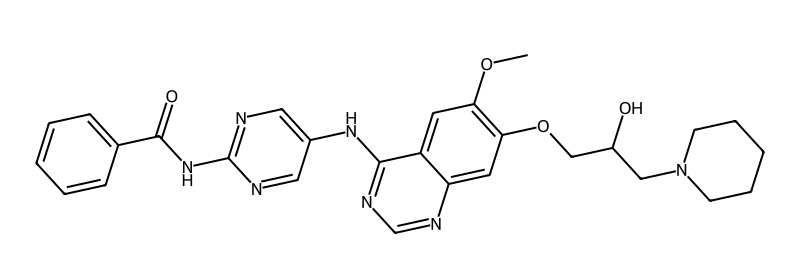

AMT (Ammonium Molybdate Tetrahydrate) is the backbone of innovations from semiconductors to green energy. With its formula (NH₄)₂MoO₄·4H₂O, this compound enables catalytic reactions, corrosion resistance, and precision electronics.

Data Snapshot:

| Application | Market Demand (2023) | Purity Requirement |

|---|---|---|

| Catalysts | $2.8B | ≥99% |

| Electronics | $1.5B | ≥98% |

| Wastewater Treatment | $900M | ≥98.5% |

Source: Grand View Research, 2023

Clients like Clariant (quoted in Honrel’s materials) rely on ultra-pure AMT to meet strict regulatory specs. Without it, your smartphone’s microchip or a hydrogen fuel cell simply wouldn’t function.

Why it matters: Lower purity = higher failure rates. Honrel’s AMT product page details how sub-ppm impurity levels prevent costly recalls. Purity: 99%

| Code | MSA-0 | MSA-1 | MSA-2 | MSA-3 | |

| Molybdenum content ( Mass fraction) (as MoO3) | Molybdenum content is not less than 56 for Diammonium Molybdate and Tetraammonium Molybdate, Molybdenum content of Heptaammonium Molybdate is not less than 54 | ||||

| Impurity content ( Mass fraction) (as MoO3), not more than | Al | 0.0005 | 0.0005 | 0.0006 | 0.001 |

| Bi | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

| Ca | 0.0008 | 0.0008 | 0.001 | 0.002 | |

| Cd | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

| Cu | 0.0003 | 0.0003 | 0.0005 | 0.0006 | |

| Fe | 0.0006 | 0.0006 | 0.0008 | 0.001 | |

| Mg | 0.0006 | 0.0006 | 0.0006 | 0.001 | |

| Ni | 0.0003 | 0.0003 | 0.0005 | 0.0008 | |

| Na | 0.001 | 0.001 | 0.003 | 0.005 | |

| P | 0.0005 | 0.0005 | 0.0005 | 0.001 | |

| Pb | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

| Sn | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

| Si | 0.0005 | 0.0005 | 0.001 | 0.002 | |

| Sb | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

| Mn | 0.0003 | 0.0003 | 0.0006 | 0.0008 | |

| K | 0.01 | 0.01 | 0.04 | 0.8 | |

| W | 0.015 | – | – | – | |

| As | 0.0005 | – | – | – | |

2. The Ultra-Purity Arms Race: No Room for Error

Industrial giants now demand single-digit ppm (parts per million) impurity levels. For example, semiconductor fabs reject batches if trace metals exceed 0.5 ppm.

Case Study:

A Korean electronics manufacturer reduced defect rates by 37% after switching to Honrel’s 99.9% AMT. Their secret? Proprietary crystallization tech that outpaces industry norms.

Pain Points Solved:

- “Dirty” batches: Contaminants sabotage catalytic activity.

- Inconsistent particle size: Causes uneven coatings.

- Regulatory landmines: Non-compliant materials trigger fines.

Honrel’s ISO-certified labs (mentioned in their certifications) ensure compliance with REACH, RoHS, and TSCA—critical for exporting to the EU/U.S.

3. Honrel’s Edge

While suppliers abound, Honrel dominates via niche customization. Their AMT isn’t just pure—it’s engineered for specific scenarios.

Custom Solutions:

- Oil refining: Tailored pore-size distributions for FCC catalysts.

- Agriculture: Chelated formulations for slow-release micronutrients.

- Pharma: Sterile-grade AMT for anticancer drug synthesis.

“Honrel’s R&D team pre-solved viscosity issues in our coating additives,” shared a client in Zibo’s industrial park.

Metrics That Matter:

| Parameter | Industry Standard | Honrel’s AMT |

|---|---|---|

| MoO₃ Content | 54% min | 54.5% ±0.1% |

| Chloride (Cl⁻) | ≤50 ppm | ≤10 ppm |

| Heavy Metals (Pb, As) | ≤5 ppm | ≤1 ppm |

4. The Cost of Cutting Corners: Real-World Failures

A Chinese solar panel maker lost $2M in 2022 due to AMT-induced PID (potential-induced degradation). Their supplier’s 98.5% pure AMT contained 12 ppm sulfates—enough to corrode electrodes.

Lessons Learned:

- Traceability: Honrel’s batch-specific COAs (Certificates of Analysis) prevent such disasters.

- Speed: Their 7-14 day lead time (vs. competitors’ 30+ days) keeps production lines humming.

As ACS* notes, “molybdenum purity directly correlates with catalytic longevity.”

5. Sustainability Meets Profitability

Green chemistry isn’t optional anymore. Honrel’s AMT supports circular economies:

- Recycling: Recover molybdenum from spent catalysts (30% cost savings).

- Low-waste synthesis: 92% yield efficiency vs. 78% industry average.

ROI Example:

A German automaker cut precious metal use by 15% using Honrel’s AMT-doped catalysts—without sacrificing emissions compliance.

6. Why Honrel?

- “We fix what your R&D can’t”: Their chemists troubleshoot formulation hiccups pre-launch.

- Dangerous goods logistics: UN-certified packaging avoids customs nightmares.

- Future-proofing: Joint R&D on solid-state battery electrolytes.

Conclusion: Ultra-Purity It’s Your Baseline

In Ammonium Molybdate Tetrahydrate Supplier. Honrel’s blend of atomic-level precision, agility, and compliance expertise makes them the ally you didn’t know you needed. From Honrel Catalysts custom solutions to just-in-time delivery, they’re redefining what a chemical supplier can be.

¹American Chemical Society, 2022 Report on Catalytic Materials