![]()

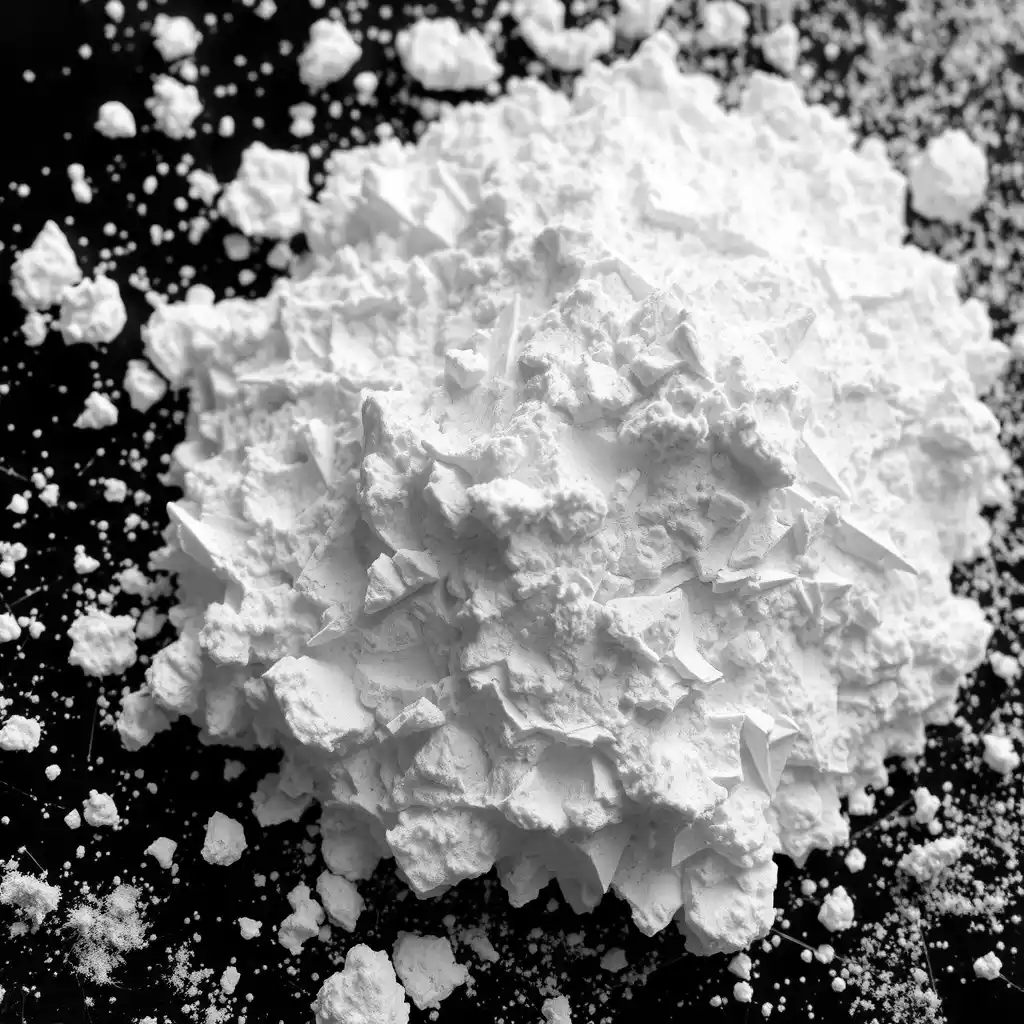

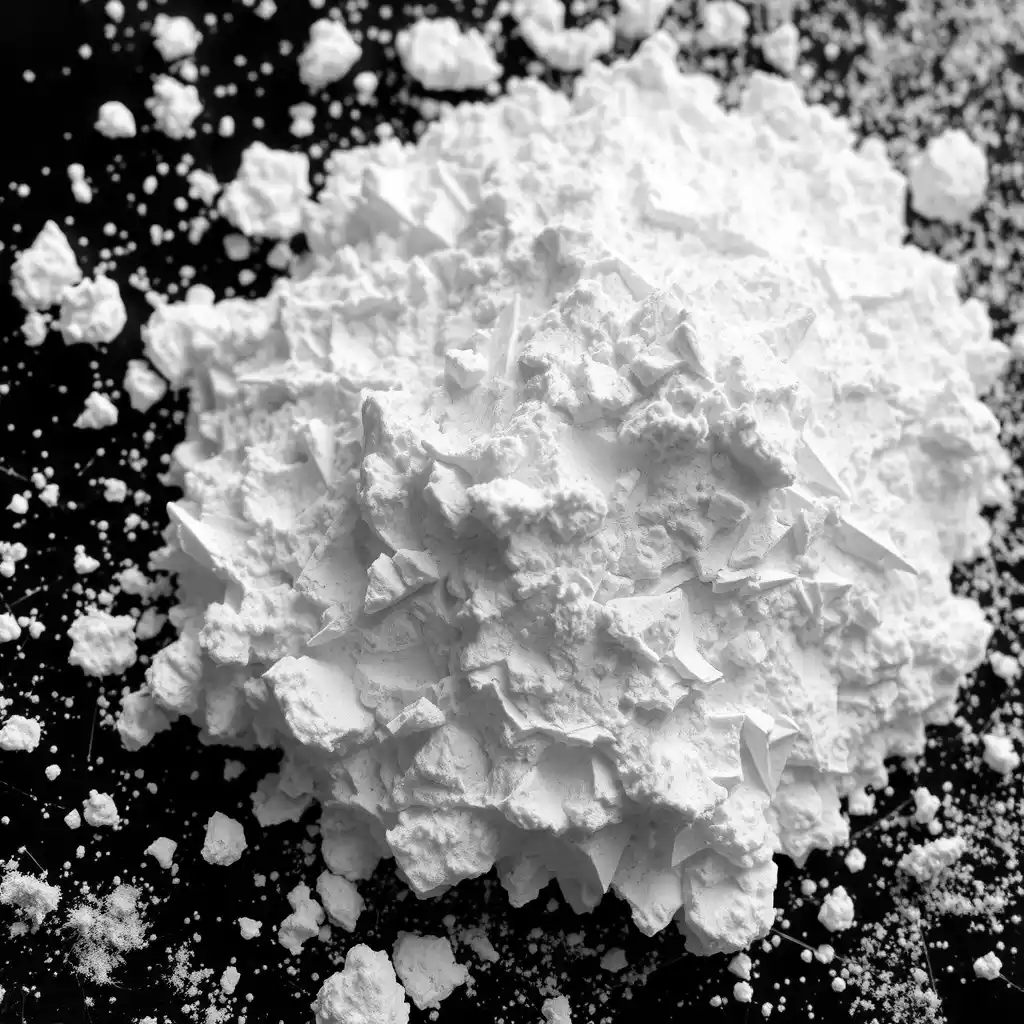

Best White Fused Alumina Price

Best White Fused Alumina Price: A Comprehensive Guide to Finding Affordable and High-Quality Materials

White fused alumina (WFA) is a highly sought-after material in industries that require high-performance abrasives, refractory products, and advanced ceramics. Known for its hardness, durability, and thermal stability, white fused alumina is widely used in abrasive and refractory applications. However, when sourcing this valuable material, one of the key considerations for businesses is securing the best white fused alumina price without compromising on quality. In this article, we will discuss factors influencing the price of white fused alumina, strategies to find competitive pricing, and the advantages of sourcing from reliable suppliers.

Table of Contents

1. What is White Fused Alumina?

White fused alumina is a synthetic abrasive material produced by melting high-purity alumina in an electric arc furnace at temperatures over 2,000°C. This process results in a high-purity, crystalline form of aluminum oxide, which is known for its hardness and resistance to chemical attack. White fused alumina is commonly used in the manufacturing of abrasives, refractories, and advanced ceramics.

Key Characteristics of White Fused Alumina:

- Hardness: 9 on the Mohs scale, making it ideal for abrasive applications.

- Purity: Can reach up to 99% Al₂O₃, ensuring high performance in demanding conditions.

- Thermal Stability: Withstands extreme temperatures (up to 1,800°C), making it suitable for refractory materials.

- Chemical Resistance: Excellent resistance to acids, alkalis, and other corrosive substances.

2. Factors That Influence the Best White Fused Alumina Price

The price of white fused alumina is influenced by several factors, including production costs, quality, demand, and supply chain considerations. Here are the main elements that determine the cost of white fused alumina:

A. Raw Material Costs

The cost of raw materials, particularly bauxite, plays a significant role in determining the overall price of white fused alumina. Bauxite is the primary source of aluminum oxide, and fluctuations in its price can affect the cost of production.

B. Energy Costs

White fused alumina is produced by melting alumina in an electric arc furnace, which requires a substantial amount of energy. Energy prices, particularly electricity, can significantly influence the final price of the material.

C. Production Scale and Efficiency

Larger production scales tend to result in lower costs due to economies of scale. Advanced manufacturing techniques that increase efficiency, such as continuous furnaces and optimized cooling processes, can also help reduce production costs and, subsequently, the price of white fused alumina.

D. Purity and Quality

Higher purity grades of white fused alumina generally come at a higher price. For example, white fused alumina with 99% or more Al₂O₃ content is typically more expensive than lower-grade materials. The specific application for which the material is intended will also affect the price.

E. Geographic Location and Supply Chain

Transportation and logistics costs also impact the price of white fused alumina, especially if it needs to be shipped internationally. Suppliers in regions with direct access to raw materials or manufacturing facilities may offer better prices compared to those farther away from production hubs.

3. Strategies to Find the Best White Fused Alumina Price

When looking for the best price for white fused alumina, there are several strategies businesses can employ to ensure they are getting the most value for their investment:

A. Bulk Purchasing

Purchasing white fused alumina in bulk quantities is one of the most effective ways to secure lower prices. Suppliers often offer volume discounts for large orders, which can significantly reduce the cost per unit. For companies that regularly use white fused alumina, bulk purchasing can be a cost-effective long-term strategy.

B. Comparison Shopping

Before making a purchase, it’s important to compare prices from multiple suppliers. Prices for white fused alumina can vary widely depending on the supplier’s location, the quality of the material, and other factors. Use online marketplaces and supplier websites to request quotes and compare pricing options.

C. Long-Term Supplier Relationships

Establishing a long-term relationship with a supplier can also lead to better pricing over time. Regular customers may receive preferential pricing, discounts, or other incentives that can help reduce the overall cost of white fused alumina.

D. Negotiate Terms

Don’t hesitate to negotiate terms with suppliers, especially if you are purchasing large quantities. You may be able to negotiate better pricing, payment terms, or additional services such as faster delivery or custom packaging.

For more information on purchasing materials in bulk, check out our Abrasive Materials section.

4. Comparing White Fused Alumina Prices by Suppliers

Prices for white fused alumina can vary based on location, production costs, and other factors. Here’s a comparison of prices from different suppliers to give you an idea of what you might expect:

| Supplier | Price Range (USD/MT) | Purity | Product Type |

|---|---|---|---|

| WhiteC | $600 – $1,100 | 99% | Abrasives, Refractories |

| IndiaM | $650 – $1,200 | 99% | Abrasives, Ceramics |

| Honrel Abrasives | $550 – $1,000 | 99.5% | Abrasives, Polishing |

| StoneC | $580 – $1,150 | 99% | Refractories, Industrial Use |

| Wabras | $630 – $1,100 | 99.5% | Abrasives, Cutting Tools |

Note: Prices are approximate and vary based on quantity, specific grade, and location.

As you can see, prices tend to fall within a certain range but may vary based on the grade and the supplier’s specific terms. It is always advisable to confirm current prices directly with the supplier.

5. Why Quality is Just as Important as Price

While securing the best price for white fused alumina is important, it’s equally critical to consider the material’s quality. White fused alumina is used in demanding applications, including abrasives, refractories, and advanced ceramics, where performance is crucial.

Lower-grade materials might save money upfront but could lead to subpar results in the final product, higher operational costs, and increased maintenance over time. Investing in higher-quality white fused alumina can ultimately save money in the long run by enhancing product efficiency, reducing downtime, and improving the overall performance of your processes.

6. Environmental Considerations in White Fused Alumina Production

Environmental factors also play a role in the pricing of white fused alumina. The production process involves energy-intensive operations that can have a significant carbon footprint. As the global demand for sustainable practices increases, many manufacturers are adopting greener production methods to reduce their environmental impact.

For example, some suppliers are investing in energy-efficient production techniques, using renewable energy sources, or recycling materials. These efforts may increase production costs but could contribute to a more sustainable and environmentally friendly product.

7. Global Demand and Market Trends for White Fused Alumina

The global demand for white fused alumina has been steadily increasing, driven by its widespread use in abrasives, refractories, and ceramics. The Asia-Pacific region, particularly China and India, is the largest producer of white fused alumina, but demand is growing in North America, Europe, and other regions as well.

Key market trends include:

- Technological Advancements: Ongoing innovations in production technology are improving the efficiency and quality of white fused alumina.

- Rising Demand for Abrasives and Refractories: The construction, automotive, and steel industries are major consumers of white fused alumina, driving its demand.

- Sustainability Focus: As mentioned earlier, there is increasing emphasis on sustainable production practices, which may influence the price and availability of white fused alumina.

8. How to Source the Best White Fused Alumina for Your Business

To source the best white fused alumina, start by researching suppliers that meet your specific requirements, such as the desired grade, quantity, and application. Look for established suppliers that offer competitive pricing, quality assurance, and reliable delivery.

Additionally, it’s important to check certifications and quality standards, as reputable suppliers will often have their materials tested for consistency and quality. For businesses looking to purchase white fused alumina in bulk, long-term relationships with trusted suppliers can help secure favorable pricing and better overall service.

For more about purchasing from a trusted supplier, visit our Chemical Raw Materials page.

9. FAQs on Best White Fused Alumina Price

What is the best white fused alumina price per ton?

The price of white fused alumina typically ranges from $550 to $1,200 per metric ton, depending on the grade and supplier.

How can I get a discount on white fused alumina?

Purchasing in bulk, establishing long-term relationships with suppliers, and negotiating prices can help you secure discounts on white fused alumina.

Is the quality of white fused alumina consistent across all suppliers?

No, the quality of white fused alumina can vary. It’s important to source from reputable suppliers who provide quality assurance and test their products.

Can I purchase white fused alumina directly from manufacturers?

Yes, many manufacturers sell white fused alumina directly to businesses, often offering better pricing than distributors.

What are the main uses of white fused alumina?

White fused alumina is used in abrasives, refractories, ceramics, and other industrial applications due to its hardness and thermal stability.

Does white fused alumina have any environmental impact?

The production of white fused alumina can be energy-intensive, but many suppliers are adopting sustainable practices to reduce its environmental footprint.

Can I get customized grades of white fused alumina?

Yes, some suppliers offer customized grades of white fused alumina based on specific needs, such as for abrasives or refractory applications.

Where can I buy the best white fused alumina?

Reputable suppliers like Honrel offer a wide range of white fused alumina products at competitive prices.

By following the strategies mentioned above and choosing the right suppliers, businesses can secure the best white fused alumina price while ensuring high-quality materials for their manufacturing needs.