![]()

High Refractoriness Tabular Alumina

High Refractoriness Tabular Alumina: An In-Depth Look at Its Properties and Applications

High refractoriness tabular alumina is one of the most important materials in the world of refractories, known for its exceptional thermal stability, high strength, and resistance to wear and corrosion. This unique material, produced through a specific manufacturing process involving the heating of alumina at extremely high temperatures, is widely used in industries where high-performance materials are essential for maintaining structural integrity under extreme conditions.

In this article, we will delve into the characteristics, manufacturing process, key applications, and benefits of high refractoriness tabular alumina, and explore why it is a preferred choice in various industrial sectors. Whether you are in the construction, steel manufacturing, or electronics industries, understanding this material’s qualities can enhance your decision-making when selecting the right raw materials for your needs.

Table of Contents

1. What is High Refractoriness Tabular Alumina?

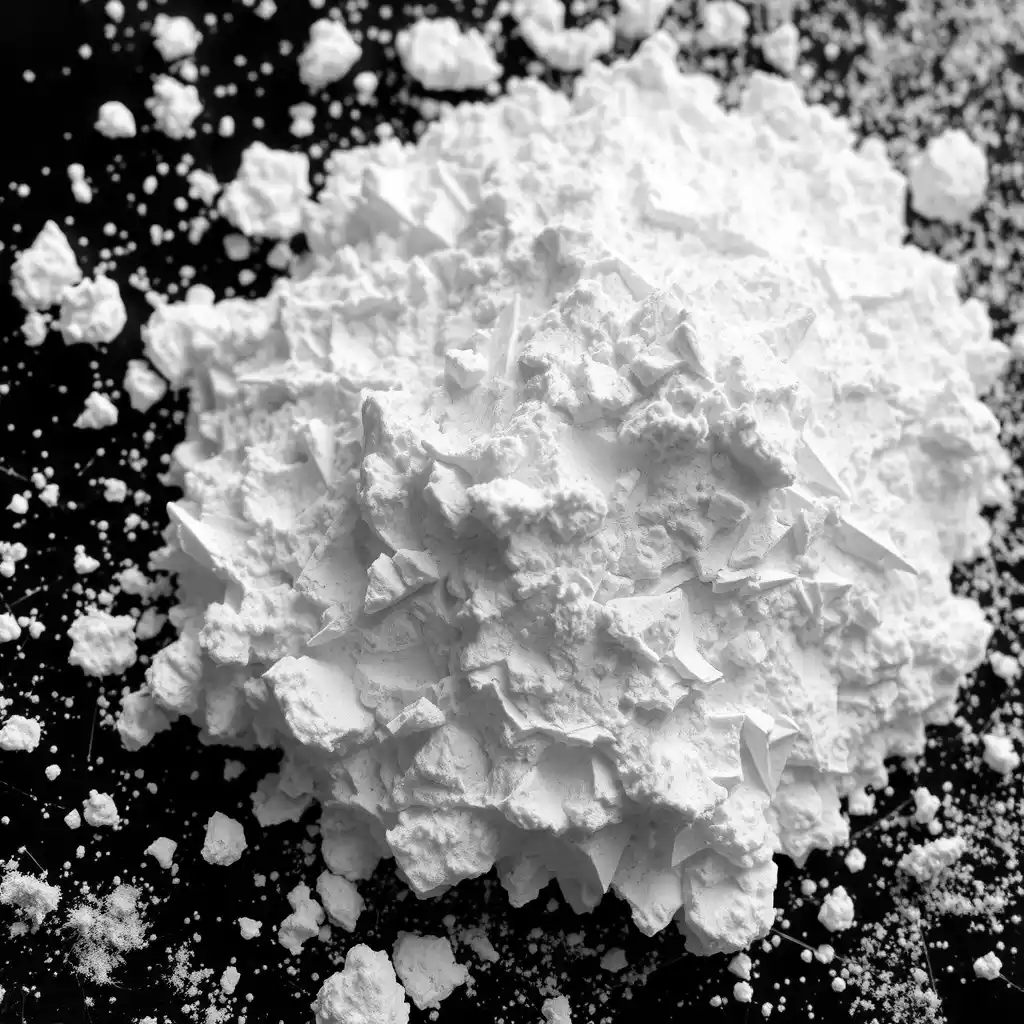

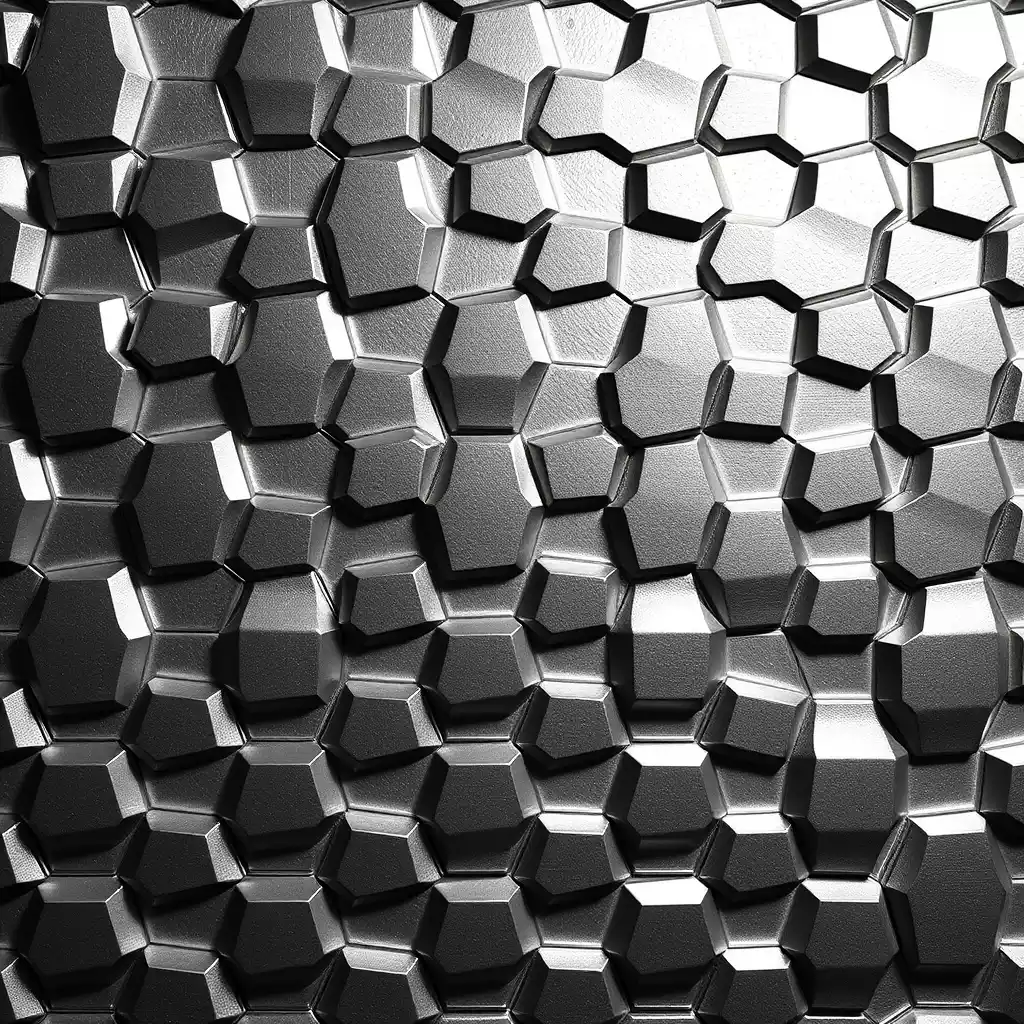

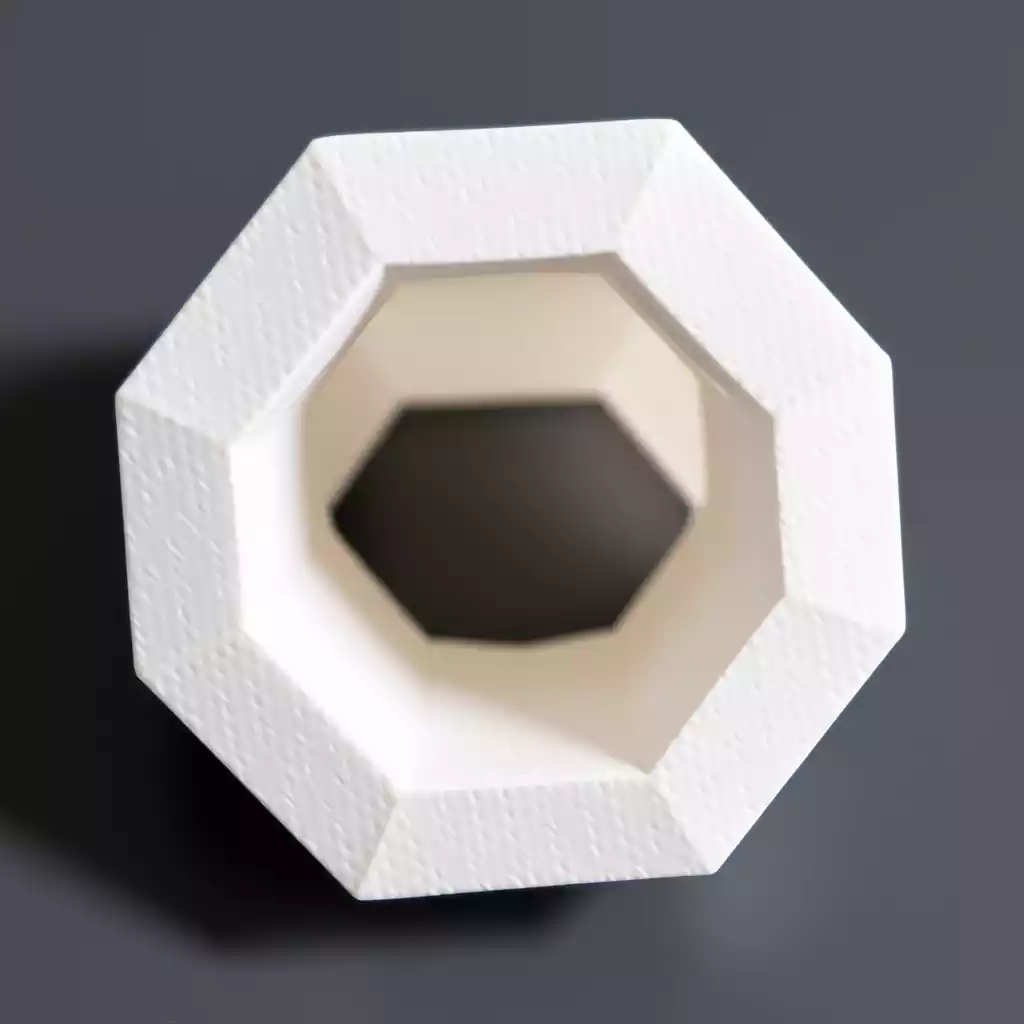

High refractoriness tabular alumina is a type of alumina (Al₂O₃) that is specifically engineered to possess excellent thermal stability, high mechanical strength, and low thermal expansion. Unlike regular alumina, tabular alumina undergoes a special manufacturing process that involves heating alumina at temperatures exceeding 1,800°C, which results in the formation of large, hexagonal crystals. These large crystals contribute to the material’s high refractoriness (resistance to heat and thermal shock), making it ideal for applications where materials are exposed to extreme temperatures.

Tabular alumina is produced through the fusion of high-quality bauxite, which is then subjected to a sintering process to form a highly dense and durable material. The result is a material with minimal porosity, superior strength, and the ability to withstand temperatures of up to 1,800°C without deforming or degrading.

For further understanding of refractory materials, visit Honrel’s Refractory Materials page.

2. The Manufacturing Process of High Refractoriness Tabular Alumina

The production of high refractoriness tabular alumina follows a precise process to ensure the material’s optimal properties:

Step 1: Sourcing Raw Materials

The process begins with selecting high-quality bauxite, the primary source of alumina. The bauxite is carefully processed to extract pure alumina, which is then used as the feed material for fusion.

Step 2: Fusion and Sintering

The alumina is subjected to high-temperature fusion in an electric arc furnace. The temperatures in the furnace typically reach up to 1,800°C, causing the alumina particles to melt and crystallize into large tabular-shaped crystals. This process is essential for achieving the material’s high refractoriness and strength.

Step 3: Cooling and Sieving

After the fusion process, the material is gradually cooled and then sieved to remove any fine particles. The remaining tabular alumina is then classified based on its particle size and ready for various applications.

The unique microstructure of tabular alumina, with its large crystals and minimal porosity, contributes to its exceptional thermal resistance, making it ideal for refractory and abrasive uses.

3. Key Properties of High Refractoriness Tabular Alumina

High refractoriness tabular alumina exhibits several properties that make it ideal for use in extreme environments:

- High Refractoriness: Tabular alumina can withstand continuous exposure to temperatures as high as 1,800°C without deteriorating, making it one of the best materials for high-temperature applications.

- Low Thermal Expansion: The low thermal expansion coefficient of tabular alumina ensures that it maintains its structural integrity when exposed to rapid temperature changes, reducing the risk of thermal shock.

- High Mechanical Strength: The large crystalline structure of tabular alumina provides superior mechanical strength, even at high temperatures, making it ideal for use in furnace linings and other high-stress environments.

- Corrosion Resistance: Tabular alumina exhibits excellent resistance to chemical corrosion, particularly in harsh environments like steelmaking and high-temperature kiln operations.

- Durability: Due to its low porosity and dense microstructure, tabular alumina resists wear and abrasion, extending the lifespan of equipment that uses it.

For more details on the unique properties of alumina, explore Honrel’s Material Catalog.

4. Applications of High Refractoriness Tabular Alumina

The high refractoriness and exceptional strength of tabular alumina make it suitable for a wide range of applications, particularly in industries requiring heat-resistant materials.

Refractory Applications

Tabular alumina is commonly used in the production of refractory materials, including bricks and castables, which are used for lining furnaces, kilns, and reactors. Its ability to withstand high temperatures and thermal shock makes it ideal for environments such as steelmaking and cement production, where temperatures often exceed 1,500°C.

Steelmaking and Foundries

In steelmaking, tabular alumina is used as a key component in linings for electric arc furnaces and ladles, where it helps protect against the wear and corrosion caused by molten metal. It is also used in the production of castable refractories, which are poured into molds to form furnace linings.

Ceramic Industry

Tabular alumina is often used as a component in the production of advanced ceramics, particularly in high-performance applications like aerospace, automotive, and electronics. Its thermal stability and strength are critical in ensuring the longevity and reliability of ceramic components exposed to extreme heat.

Learn more about our high-quality refractory materials.

Thermal Insulation

In addition to its use in refractory applications, tabular alumina is also used in thermal insulation materials, such as those used in high-temperature applications like gas turbines and reactors. The low thermal conductivity of tabular alumina helps reduce heat loss and protect sensitive equipment.

5. Benefits of Using High Refractoriness Tabular Alumina

High refractoriness tabular alumina provides several significant benefits to industries that require high-performance materials:

- Superior Thermal Stability: It can withstand extreme temperatures without degrading, providing long-term durability in high-heat environments.

- Enhanced Performance in High-Temperature Applications: The material’s ability to resist thermal shock, high-pressure environments, and corrosive conditions makes it indispensable in steel production, foundries, and kiln operations.

- Cost Efficiency: Although it may have a higher initial cost compared to other refractory materials, tabular alumina’s durability and longevity lead to long-term cost savings by reducing the frequency of material replacements.

- Environmentally Friendly: Being made from naturally abundant materials, tabular alumina is a sustainable option for industries looking to reduce their environmental footprint.

6. Comparison with Other Refractory Materials

When considering tabular alumina for your applications, it is important to compare it to other types of refractory materials to determine the best fit. Here’s a quick comparison:

| Material | High Refractoriness Tabular Alumina | Normal Alumina | Silicon Carbide |

|---|---|---|---|

| Refractoriness | Up to 1,800°C | 1,300°C to 1,500°C | Up to 1,600°C |

| Thermal Expansion | Low | Moderate | High |

| Mechanical Strength | High | Moderate | Very High |

| Corrosion Resistance | Excellent | Moderate | Good |

| Cost | High | Low | Moderate to High |

Tabular alumina excels in applications requiring high thermal stability, while silicon carbide may be chosen for environments that require both high temperature and wear resistance.

7. Sourcing High-Quality Tabular Alumina

To ensure you are getting the best material for your industrial applications, it’s crucial to source high-quality tabular alumina from a trusted supplier. At Honrel, we offer premium-grade high refractoriness tabular alumina, sourced from reputable manufacturers and suitable for a wide range of industries.

By choosing quality tabular alumina, you ensure that your equipment will last longer, perform better, and withstand extreme conditions without degradation.

8. Future Trends in the Use of Tabular Alumina

The demand for high refractoriness tabular alumina is expected to increase as industries such as steelmaking, ceramics, and aerospace continue to evolve. With the increasing focus on energy efficiency and sustainability, tabular alumina’s ability to withstand high temperatures while maintaining structural integrity will remain a critical factor in its continued use.

Innovations in production processes are also likely to make tabular alumina more cost-effective, widening its applications in industries requiring advanced materials with superior thermal and mechanical properties.

9. Conclusion

High refractoriness tabular alumina is a material of exceptional quality and versatility, offering unmatched thermal stability, strength, and resistance to wear and corrosion. Whether used in refractory applications, steelmaking, or advanced ceramics, its high-performance characteristics make it a vital material in industries where durability under extreme conditions is paramount.

To learn more about how tabular alumina can benefit your business, visit Honrel’s Material Solutions.

Frequently Asked Questions (FAQs)

1. What is high refractoriness tabular alumina used for?

It is primarily used in refractory applications, including furnace linings, steelmaking, and advanced ceramics, where high thermal stability and strength are needed.

2. How is tabular alumina produced?

It is produced by heating alumina at high temperatures in an electric arc furnace to form large, tabular-shaped crystals with minimal porosity.

3. Can tabular alumina withstand extreme temperatures?

Yes, tabular alumina can withstand temperatures up to 1,800°C without degrading, making it ideal for high-temperature applications.

4. What makes tabular alumina different from other alumina types?

Tabular alumina has a unique crystal structure and lower thermal expansion, offering superior thermal stability and strength compared to other alumina types.

5. Is tabular alumina environmentally friendly?

Yes, it is made from naturally abundant materials, making it a sustainable choice for industries focused on reducing their environmental footprint.

6. Where can I buy high-quality tabular alumina?

You can purchase high-quality tabular alumina from reputable suppliers like Honrel, which offers top-grade materials for various industries.