![]()

Ruthenium Catalyst Price

The Ruthenium Catalyst Price is an important factor in the industrial landscape, influencing a variety of applications, from hydrogenation to renewable energy production. Ruthenium, a precious metal belonging to the platinum group, plays a crucial role in the chemical industry as a catalyst, particularly in fine chemical synthesis, petroleum refining, and fuel cells. Understanding the dynamics of ruthenium catalyst prices helps manufacturers, suppliers, and businesses optimize their purchasing strategies.

In this article, we will explore the various factors affecting ruthenium catalyst prices, market trends, key applications, and provide insights for businesses dealing with raw material procurement. Whether you’re an industry veteran or a newcomer to the world of catalysts, this guide will help you navigate the complexities of ruthenium pricing.

Table of Contents

What Are Ruthenium Catalysts and Why Are They Important?

Ruthenium catalysts are primarily used to speed up chemical reactions in industrial applications. These catalysts are integral to processes like hydrogenation, which is the addition of hydrogen to organic compounds, and CO oxidation, which is critical for reducing carbon emissions. Ruthenium is part of the platinum group metals, known for their stability, high melting points, and catalytic properties.

Key Applications of Ruthenium Catalysts

- Hydrogenation: Ruthenium is commonly used in the hydrogenation of organic compounds, especially in the pharmaceutical and food industries.

- Fuel Cells: Due to its excellent conductivity and efficiency, ruthenium is used in fuel cells to produce clean energy.

- Environmental Catalysis: Ruthenium catalysts are used to convert harmful gases into less harmful emissions, playing a critical role in reducing environmental pollution.

- Fine Chemical Synthesis: Ruthenium is essential in creating high-value chemicals used in industrial applications.

Internal Link: Understanding Catalyst Raw Materials

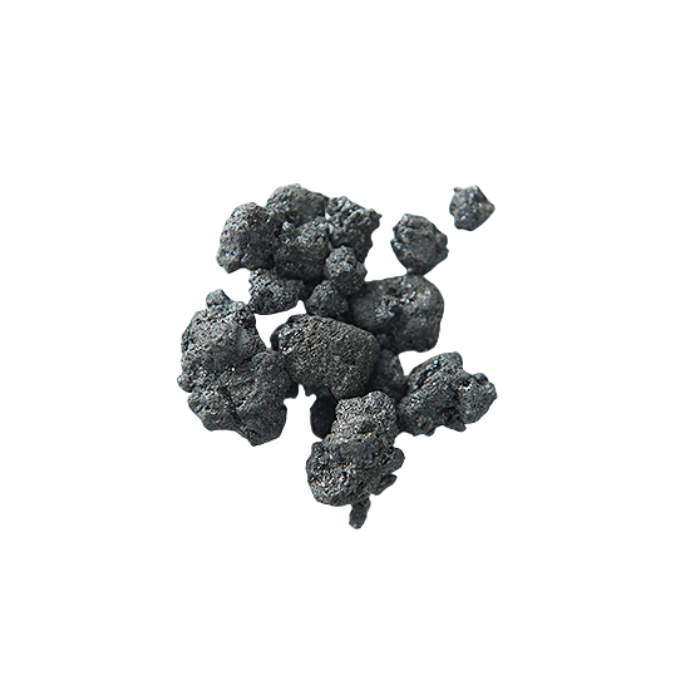

Image:

What Determines Ruthenium Catalyst Price?

1. Supply Chain Dynamics

Ruthenium catalysts are a by-product of platinum mining. As a result, disruptions in the platinum supply directly impact the availability and price of ruthenium. Global events, such as political instability or natural disasters, can cause supply shortages, leading to price surges.

2. Market Demand

The demand for ruthenium catalysts is growing, especially in industries focused on sustainability, such as renewable energy and clean fuel technologies. As these sectors expand, the need for high-quality catalysts also increases, driving up prices. Additionally, the automotive industry and fine chemical manufacturing are significant consumers of ruthenium.

3. Production Costs

The cost of producing ruthenium catalysts involves mining, refining, and synthesizing the material. This can be an expensive process due to the complexity of extraction and the low yield per ton of platinum ore. As production costs increase, manufacturers are forced to raise prices to maintain profitability.

4. Geopolitical Factors

Ruthenium mining is concentrated in certain regions, with South Africa and Russia being the primary suppliers. Political instability in these regions can lead to fluctuations in ruthenium prices.

Current Trends in Ruthenium Catalyst Prices

Price Range

As of 2024, the price of ruthenium catalysts is approximately $600–$700 per gram, which has seen a sharp increase in recent years due to supply chain disruptions and growing demand in the green energy sector. These price hikes are expected to continue as industries transition to cleaner technologies.

Price Fluctuations

In 2022, the price of ruthenium surged by over 40%, primarily due to global supply shortages. The price had been relatively stable before the surge, but since then, it has stabilized at a higher price point. The price volatility is a concern for businesses looking to secure long-term procurement contracts.

Global Market Dynamics for Ruthenium Catalysts

Demand from Key Industries

- Automotive Industry: The automotive sector, especially with stricter emission standards, has been a significant consumer of ruthenium-based catalytic converters. This trend is expected to continue as countries tighten environmental regulations.

- Renewable Energy: The push for green energy has increased the demand for ruthenium in fuel cells, a technology that powers electric vehicles and other eco-friendly applications.

- Pharmaceuticals and Fine Chemicals: Ruthenium catalysts are crucial in pharmaceutical and fine chemical manufacturing processes, where precision and efficiency are paramount.

Geographical Price Variations

Ruthenium prices can vary greatly depending on the region. For example:

- Europe and North America: Prices are generally higher due to added logistics, taxes, and stricter regulations on the chemical industry.

- Asia: In countries like China and South Korea, prices tend to be lower due to proximity to mining regions and less expensive manufacturing processes.

Internal Link: Ruthenium Applications in Industry

How to Manage Ruthenium Catalyst Price Fluctuations

Long-Term Contracts

One of the best strategies for managing price volatility is to enter into long-term contracts with suppliers. These contracts allow businesses to secure stable prices and ensure a consistent supply of catalysts, even during periods of price fluctuations.

Diversified Sourcing

Diversifying suppliers can help mitigate the risks associated with price increases. By sourcing ruthenium catalysts from multiple suppliers across different regions, companies can avoid being overly dependent on any single source.

Investing in Recycling

Recycling ruthenium from used catalysts can be a cost-effective strategy for manufacturers. Recycling reduces the need for newly mined ruthenium, thus lowering costs and minimizing the environmental impact of extraction.

Internal Link: Strategies for Sourcing Chemical Raw Materials

Case Studies: Ruthenium Catalyst in Industrial Applications

Automotive Industry

A 2023 case study in the automotive industry showed that ruthenium catalysts are crucial in the development of catalytic converters that meet stringent emission standards. Despite the rising costs, automotive manufacturers are continuing to invest in ruthenium-based solutions to meet environmental goals.

Pharmaceutical Industry

In the pharmaceutical industry, ruthenium catalysts are used in the synthesis of high-value chemicals. A study in 2022 revealed that pharmaceutical companies faced a 15% increase in production costs due to rising ruthenium prices, prompting them to explore alternative catalyst solutions.

Future Price Predictions for Ruthenium Catalysts

Price Surge Forecast

Ruthenium prices are projected to rise by an additional 15-20% by 2030, driven by continued demand in the green energy sector and increasing global adoption of fuel cell technology. Companies that use ruthenium catalysts will need to plan for these price hikes by adjusting their budgets and procurement strategies.

Sustainability and Innovation

As sustainability becomes a central focus in various industries, ruthenium catalysts’ role in reducing carbon emissions and advancing renewable energy will likely result in more stable demand. Innovations in ruthenium recycling and alternative materials may help balance price increases.

Frequently Asked Questions (FAQ)

1. What is the current price of ruthenium catalysts?

As of 2024, ruthenium catalysts are priced between $600 and $700 per gram, with fluctuations based on supply and demand factors.

2. How does geopolitical instability affect ruthenium prices?

Geopolitical issues in mining regions, such as South Africa and Russia, can lead to disruptions in supply, causing significant price increases.

3. Why is ruthenium used in hydrogenation?

Ruthenium is an excellent catalyst for hydrogenation reactions due to its high stability and ability to accelerate chemical reactions.

4. How can businesses manage ruthenium price volatility?

Enter into long-term contracts with suppliers, diversify sourcing, and consider recycling ruthenium to mitigate price fluctuations.

5. What industries rely heavily on ruthenium catalysts?

The automotive, pharmaceutical, renewable energy, and fine chemical industries are some of the largest consumers of ruthenium catalysts.

6. Will ruthenium catalyst prices continue to rise?

Yes, due to growing demand in green energy and environmental applications, prices are expected to increase by 15-20% by 2030.

7. Are there alternatives to ruthenium catalysts?

Yes, there are alternatives, such as platinum and palladium, but they come with their own set of challenges and costs.

8. How do I secure a reliable source of ruthenium catalysts?

Consider diversifying suppliers, entering long-term contracts, and working with companies that offer flexible pricing models.

Conclusion

The ruthenium catalyst price is influenced by multiple factors including market demand, supply chain dynamics, production costs, and geopolitical events. As industries continue to adopt sustainable technologies, the price of ruthenium is expected to rise, making it crucial for businesses to strategize their procurement processes. Understanding these dynamics and planning accordingly will help companies maintain competitiveness and profitability in a rapidly evolving market.

Call to Action: For businesses looking to purchase ruthenium catalysts at competitive prices, visit

Honrel’s Catalyst Section for reliable sourcing options.