![]()

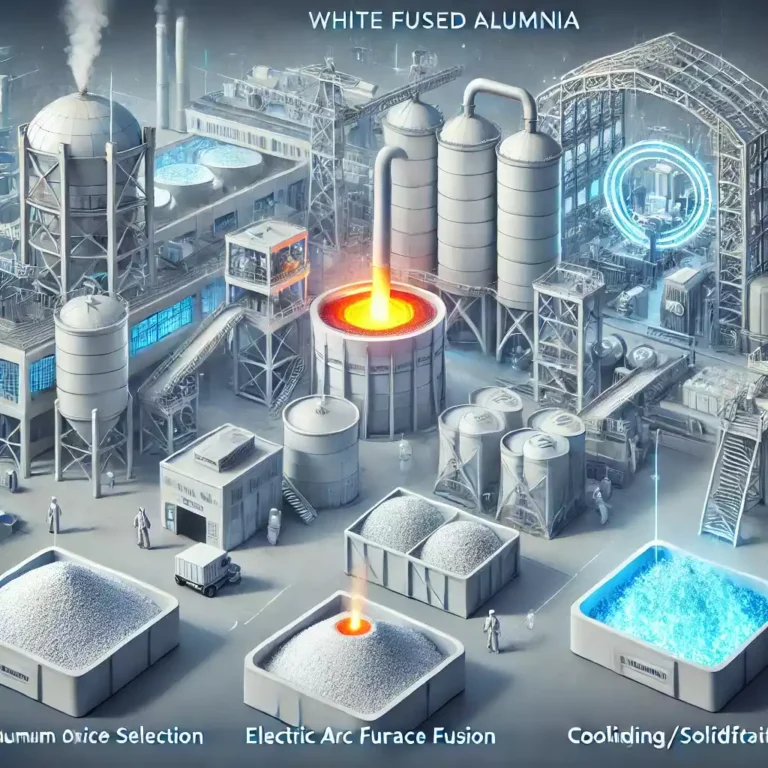

Purchase Tabular Alumina in the US Market

To purchase tabular alumina in the US, it’s essential to choose a supplier who can provide high-quality materials that meet your specific needs. Honrel stands out as a trusted supplier of abrasive and refractory materials, including tabular alumina, offering global shipping and customization options.