![]()

What is a Ruthenium Catalyst?

Introduction to Ruthenium Catalysts

At Honrel, a leading global supplier of chemical raw materials, we specialize in delivering high-performance ruthenium catalysts tailored for industrial applications. Our ruthenium on activated charcoal catalysts (CAS No. 7440-18-8) are engineered to optimize efficiency in hydrogenation, oxidation, and energy conversion processes. Designed for factories and bulk buyers across Europe, America, Asia, and the Middle East, our catalysts combine cutting-edge technology with cost-effective solutions.

Table of Contents

1. What is a Ruthenium Catalyst?

A ruthenium catalyst is a chemical accelerator where ruthenium metal is dispersed on a porous support material like activated charcoal. This combination enhances reaction rates, reduces energy consumption, and improves product yields in industrial processes.

1.1 Why Ruthenium?

- High Activity: Ruthenium’s unique electron configuration enables efficient bond-breaking and formation.

- Thermal Stability: Operates effectively at temperatures up to 500°C.

- Corrosion Resistance: Ideal for acidic or alkaline environments.

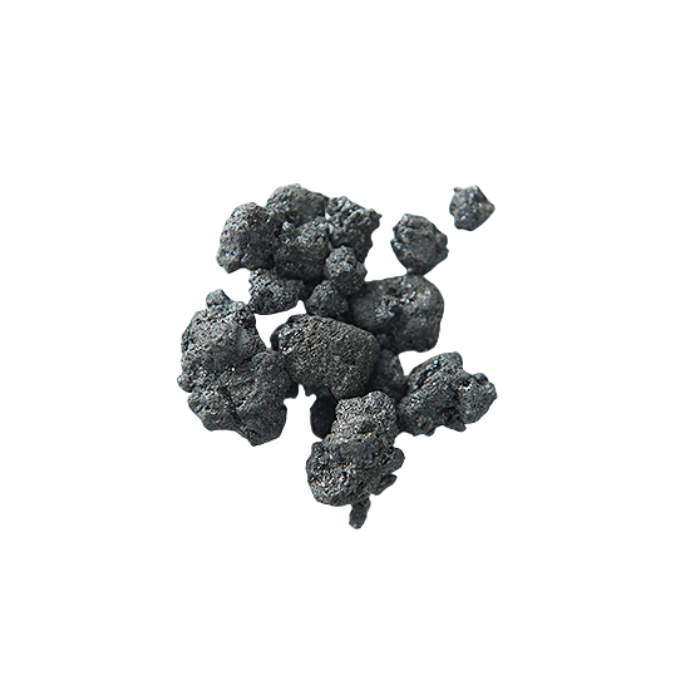

1.2 Role of Activated Charcoal

Activated charcoal (AC) acts as a high-surface-area carrier, preventing ruthenium nanoparticle agglomeration. Honrel offers AC from coconut shell, coal, wood, and peat, each optimized for specific applications.

2. Honrel’s Ruthenium Catalyst Specifications

Our ruthenium catalysts (Grades: Ru 101, Ru 103, Ru 105, Ru 107, Ru 110) are customizable to meet diverse industrial needs:

2.1 Technical Parameters

| Property | Specifications |

|---|---|

| Ruthenium Content | 0.1% – 30% (adjustable for cost or performance-driven applications) |

| Carrier Material | Coconut shell, coal, wood, peat |

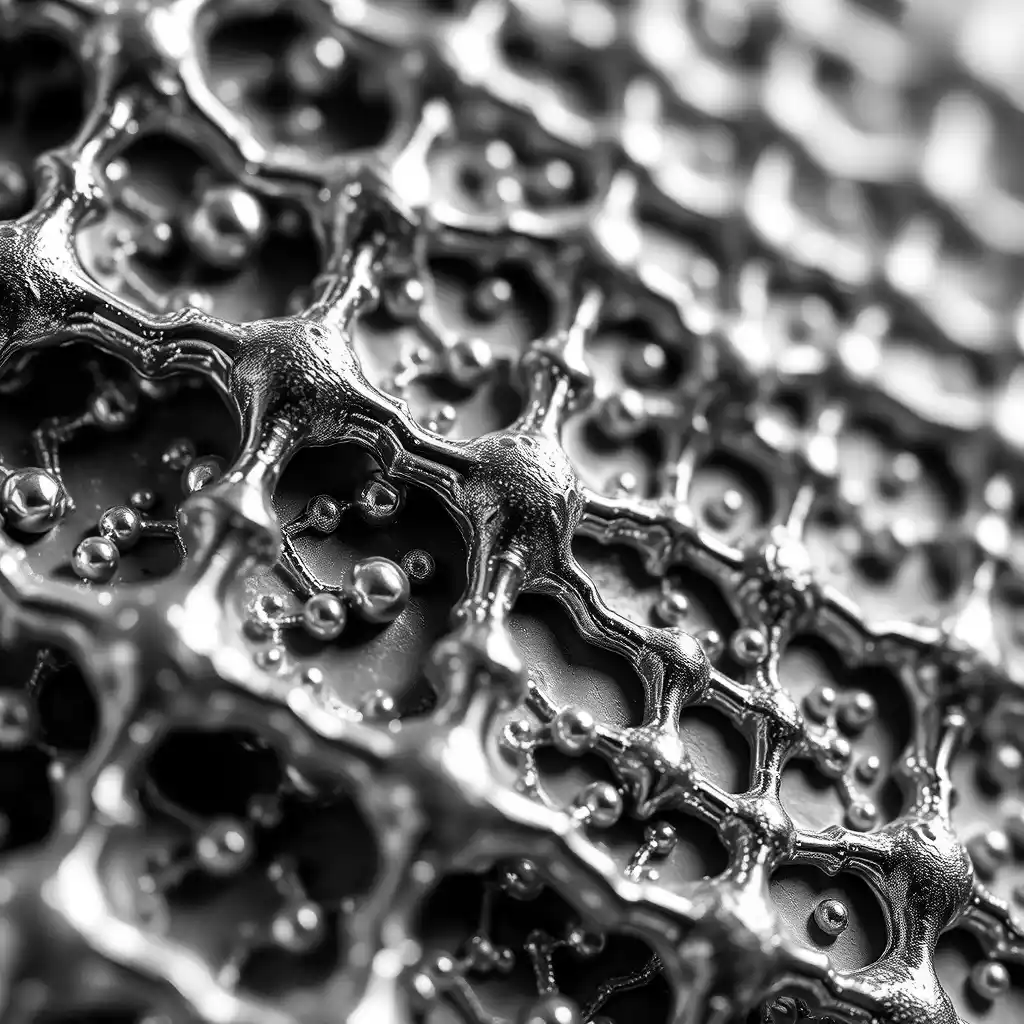

| Specific Surface Area | ≥930 m²/g (powdered AC); 750–1,320 m²/g (columnar/granular AC) |

| Metal Surface Area | 85–105 m²/g (ensures active site accessibility) |

| Particle Size | 15–100 μm (powdered); 0.8–4mm (columnar); 4–12 mesh (flaky/granular) |

| Impurities | ≤0.3% (Cu, Fe, Cr, Ni, Ag, Mg) – minimal contaminants for stable performance |

| Moisture Content | 0.1%–65% (adjustable for slurry or dry-phase reactions) |

Explore Honrel’s Ruthenium Catalyst Product Page

3. Industrial Applications of Ruthenium Catalysts

Our catalysts are trusted by industries worldwide for their versatility:

3.1 Hydrogenation Reactions

- Pharmaceuticals: Selective hydrogenation of nitro compounds to amines (e.g., paracetamol intermediates).

- Food Processing: Trans-fat reduction in vegetable oils using 10% Ru/wood AC at 150°C.

- Fine Chemicals: Production of fragrances and dyes with 5% Ru/coconut AC.

3.2 Energy & Environmental Solutions

- Ammonia Synthesis: Ru/AC (20% loading) outperforms traditional Fe catalysts at 50–100 bar pressure.

- Hydrogen Production: Efficient ammonia cracking at 600°C for clean energy.

- CO₂ Conversion: Ru-K/AC systems convert CO₂ to methane (Sabatier reaction), aiding carbon capture.

3.3 Petrochemical Refining

- Fischer-Tropsch Synthesis: Produces linear alkanes from syngas using 10% Ru/coal AC.

- Desulfurization: Removes sulfur compounds from diesel via hydrodesulfurization (HDS).

4. Why Choose Honrel’s Ruthenium Catalysts?

4.1 Customization for Global Markets

- Carrier Flexibility: Coconut shell AC (high microporosity) for small molecules; coal AC (mesopores) for petrochemicals.

- Particle Size Optimization: Match our 15–100 μm powders or 4–12 mesh granules to your reactor’s filter system.

- Ru Loading Control: From 0.1% (low-cost batch processes) to 30% (high-activity continuous reactors).

4.2 Quality Assurance

- Purity: ≤0.3% impurities ensure no catalyst poisoning.

- Durability: Particle strength ≥90% minimizes attrition in fluidized beds.

- Compliance: Meets REACH, OSHA, and ISO standards for global export.

4.3 Cost & Time Efficiency

- Bulk Discounts: Competitive pricing for factories in Europe, Japan, Russia, and Iran.

- One-Stop Supply: Pair ruthenium catalysts with our precious metals or rare earth products for streamlined procurement.

5. How to Select the Right Ruthenium Catalyst

5.1 Match Carrier Material to Your Reaction

- Coconut Shell AC: Best for hydrogen storage (microporous structure).

- Coal-Based AC: Ideal for heavy hydrocarbon processing.

- Wood AC: Cost-effective for VOC oxidation.

5.2 Consider Reactor Type

- Fixed-Bed Reactors: Use columnar AC (0.8–4mm) for low pressure drop.

- Slurry Reactors: Opt for powdered AC (30 μm) for maximum surface contact.

5.3 Request a Free Consultation

Honrel’s technical team provides free application analysis to recommend the optimal Ru grade and carrier.

6. FAQs About Ruthenium Catalysts

Q1: What is the lead time for bulk orders?

A: Most orders ship within 7–14 days, with expedited options for urgent needs.

Q2: Can Honrel customize impurity limits?

A: Yes – we adjust leaching processes to meet specific purity requirements (e.g., <0.1% Fe).

Q3: Do you provide regeneration services?

A: Yes! We recover >90% Ru from spent catalysts via acid washing or thermal treatment.

7. Partner with Honrel – Your Global Chemical Raw Material Supplier

With clients in over 15 countries, Honrel is synonymous with reliability in the chemical industry. Our Catalyst Raw Material category offers:

- Ruthenium, Palladium, and Platinum Catalysts

- Zeolites, Molecular Sieves, and Enzyme Catalysts

- Custom Blends for Niche Applications

8. Conclusion

Ruthenium catalysts are indispensable in modern industry, and Honrel delivers solutions that balance performance, cost, and scalability. Whether you’re a factory in Germany refining biofuels or a chemical plant in South Korea synthesizing pharmaceuticals, our ruthenium on activated charcoal catalysts are engineered for success.

Ready to Optimize Your Process?

Contact Honrel Today for a quote or technical consultation.