![]()

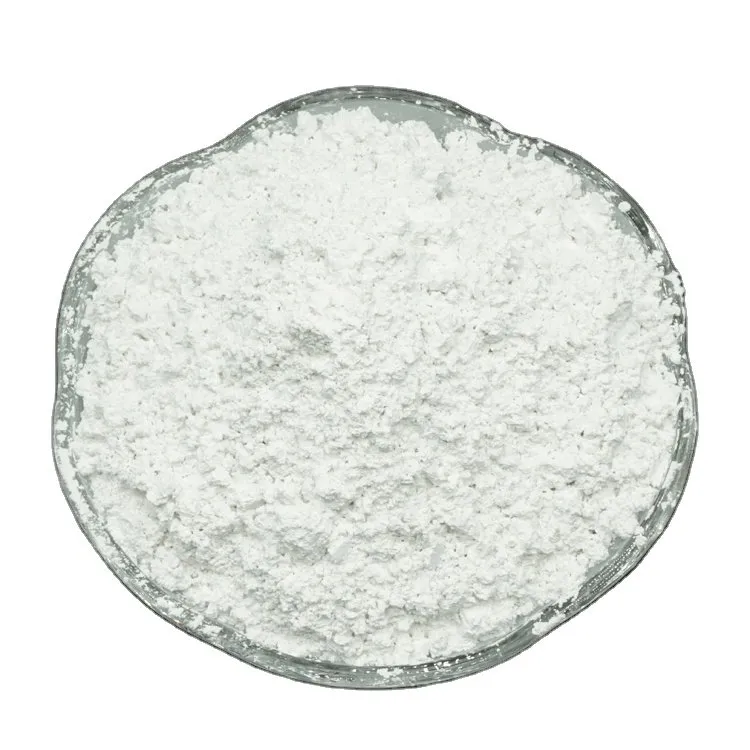

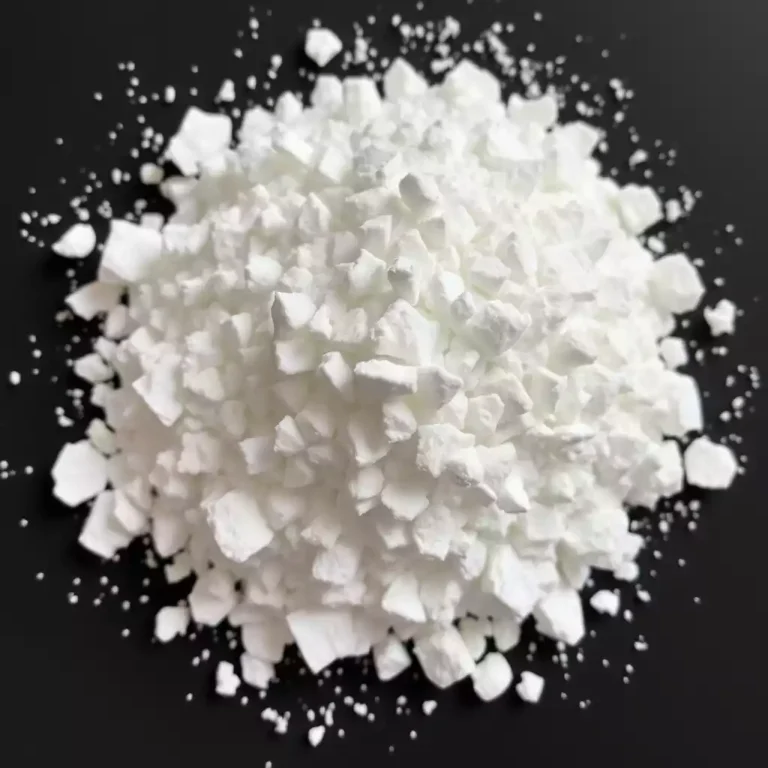

High Purity White Fused Alumina Powder

White Fused Alumina Powder is one of the most sought-after materials in the world today. This high-purity abrasive material plays a critical role in various industries, including manufacturing, automotive, and chemical processing.