![]()

White Fused Alumina Uses

White Fused Alumina Uses: Unlocking the Potential of a Versatile Material

White fused alumina (WFA) is a high-purity, versatile material that finds use in a wide range of industries. Renowned for its superior hardness, thermal stability, and chemical inertness, WFA is critical in abrasive, refractory, and precision applications. This article will delve into the diverse white fused alumina uses, exploring its vital role across multiple sectors and its undeniable advantages.

Table of Contents

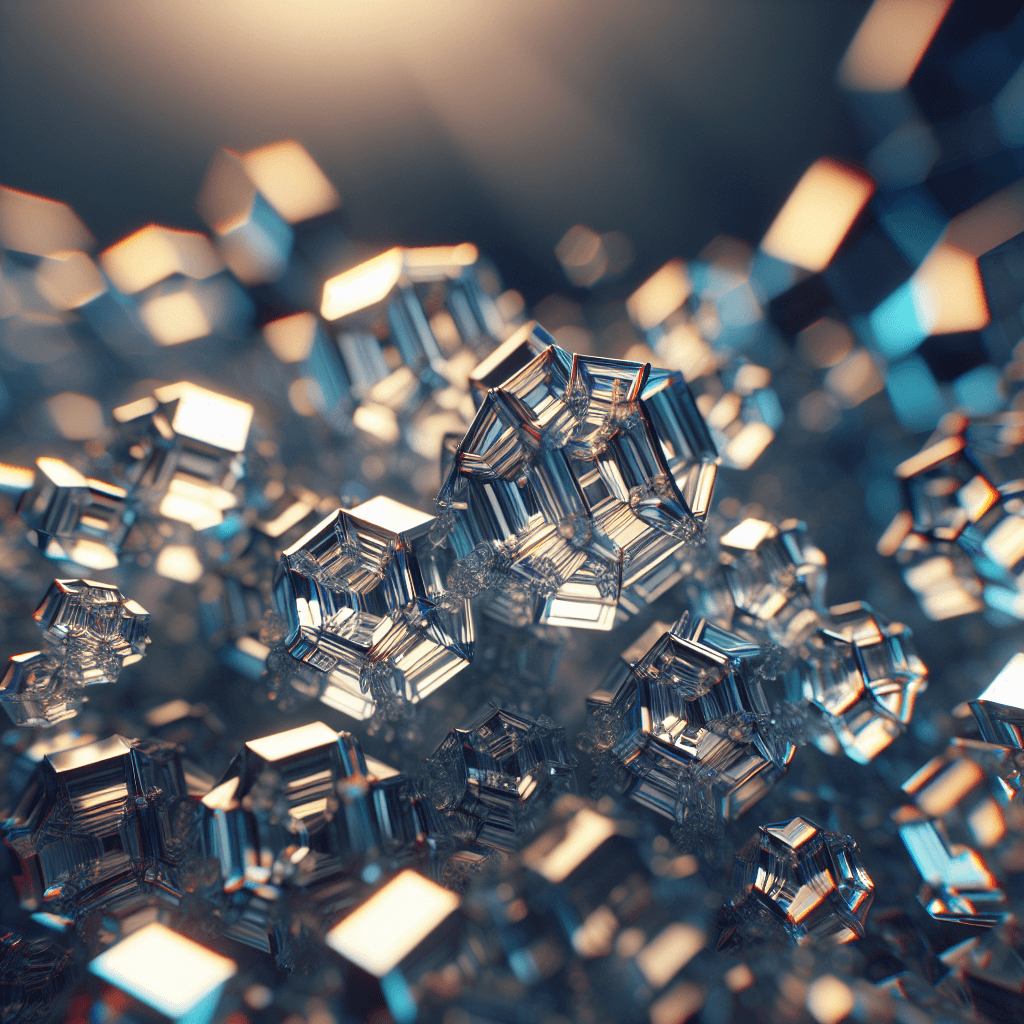

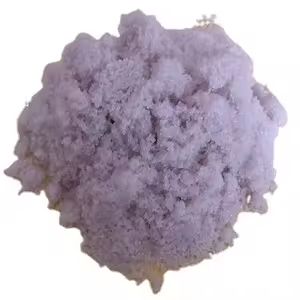

1. Introduction to White Fused Alumina

White fused alumina is a synthetic form of aluminum oxide (Al₂O₃) produced by melting alumina at temperatures exceeding 2000°C in an electric arc furnace. The result is a material with exceptional hardness, chemical resistance, and stability, making it ideal for a wide range of industrial applications.

White fused alumina is widely used in abrasives, refractories, and advanced materials. The material’s high purity and controlled crystal structure make it suitable for precision applications and demanding environments.

2. Abrasive Applications of White Fused Alumina

One of the primary uses of white fused alumina is in the production of abrasives. Due to its hardness (9 on the Mohs scale), it is perfect for applications that require material removal, surface preparation, and polishing. Some common abrasive uses include:

- Grinding Wheels: White fused alumina is used to manufacture grinding wheels for precision cutting and finishing of metals, ceramics, and composites.

- Polishing Compounds: The material is used in polishing compounds for delicate surfaces, ensuring smooth, reflective finishes.

- Sandblasting: It is an ideal abrasive media for industrial sandblasting applications due to its high toughness and low dusting.

For businesses looking for high-performance abrasives, check out Honrel’s abrasive solutions.

3. Refractory Uses of White Fused Alumina

Due to its high thermal resistance and chemical stability, white fused alumina is widely used in refractory applications. These include:

- Kiln Linings: WFA is ideal for furnace linings, where it can withstand extreme temperatures without degradation.

- Refractory Bricks: Used in the production of bricks that are resistant to heat and corrosion in high-temperature environments like steel manufacturing.

- Casting Materials: It is used in high-performance castables for the aerospace and metallurgy industries.

Explore Honrel’s refractory products to find premium-grade white fused alumina for your high-temperature applications.

4. Polishing and Grinding in Precision Industries

White fused alumina is widely used in precision grinding and polishing due to its purity and sharp edges. It is especially valuable in industries where fine surface finishes are critical, such as:

- Semiconductor Manufacturing: Used for polishing silicon wafers and other sensitive components.

- Gemstone Polishing: White fused alumina is used to polish and smooth gemstones, ensuring flawless finishes.

- Optical Components: Polishing optical surfaces and lenses for clarity and precision.

Check out Honrel’s high-purity white fused alumina powders for precision grinding and polishing needs.

5. Environmental and Water Filtration Applications

White fused alumina’s chemical stability and porosity make it suitable for environmental and water filtration applications. Some of the key uses include:

- Water Filtration: WFA is used in water treatment to remove suspended solids and contaminants, improving water quality for industrial and municipal use.

- Air Purification: White fused alumina is used in air filtration systems to capture particulate matter and pollutants.

- Catalyst Supports: It is employed as a support material for catalysts in environmental technologies like waste treatment and emissions control.

6. Medical Industry Uses of White Fused Alumina

In the medical industry, white fused alumina’s high purity and non-reactivity make it an ideal material for various applications. It is commonly used in:

- Surgical Tools: White fused alumina is used for the abrasive cleaning and polishing of surgical instruments and implants.

- Medical Devices: It is also used in the production of high-precision medical components, where contamination control is essential.

7. Aerospace and Automotive Industries

The aerospace and automotive industries rely on white fused alumina for several demanding applications, including:

- Blasting for Surface Preparation: White fused alumina is used to prepare metal surfaces for painting and coating applications in aircraft and automotive manufacturing.

- Coating Systems: It serves as a base for protective coatings on metal parts, enhancing resistance to heat, corrosion, and wear.

8. Differences Between White Fused Alumina and Other Fused Aluminas

White fused alumina differs from brown fused alumina in several key areas, including:

| Feature | White Fused Alumina | Brown Fused Alumina |

|---|---|---|

| Purity | >99% Al₂O₃ | ~95% Al₂O₃ |

| Color | White | Brown |

| Hardness | Slightly harder | Slightly softer |

| Applications | Precision grinding, medical uses | General-purpose abrasives |

| Cost | Higher due to higher purity | More affordable |

White fused alumina’s higher purity makes it suitable for precision applications, while brown fused alumina is more commonly used in general abrasive applications.

9. Industrial Uses of White Fused Alumina in Coatings

In addition to its use in abrasives and refractories, white fused alumina plays a significant role in the coating industry. Its fine, durable particles are utilized for:

- Protective Coatings: White fused alumina is used in coatings to provide resistance to wear, corrosion, and high temperatures in industrial environments.

- Paint and Surface Finishing: It is also used in paint formulations to enhance the durability and abrasion resistance of the final product.

10. The Future of White Fused Alumina Applications

As industries evolve and new technologies emerge, the demand for white fused alumina is expected to continue growing. Future applications include:

- Advanced Ceramic Production: WFA’s purity and thermal stability make it ideal for manufacturing advanced ceramics used in electronics and aerospace.

- Battery Materials: White fused alumina is being explored for use in battery technologies, where its high thermal stability and conductive properties can be utilized.

As industries become more innovative, white fused alumina will likely play a key role in the development of new materials and applications.

Frequently Asked Questions (FAQs)

1. What are the main white fused alumina uses?

White fused alumina is used in abrasives, refractories, polishing, water filtration, and in industries such as aerospace and automotive.

2. How does white fused alumina differ from brown fused alumina?

White fused alumina has higher purity and is harder, making it ideal for precision applications, while brown fused alumina is typically used for general abrasives.

3. Can white fused alumina be used in high-temperature applications?

Yes, white fused alumina is highly resistant to heat, making it suitable for use in furnaces, kilns, and other high-temperature environments.

4. Is white fused alumina environmentally friendly?

Yes, it is non-toxic, recyclable, and used in water filtration and air purification systems.

5. Where can I buy high-quality white fused alumina?

You can source high-quality white fused alumina from Honrel, a leading supplier of chemical raw materials worldwide.

Conclusion: Why Choose White Fused Alumina?

White fused alumina is a versatile and high-performance material that meets the demanding needs of various industries. Whether you are working in abrasives, refractories, precision polishing, or environmental applications, WFA provides exceptional benefits, including:

- High Purity: Ensures minimal contamination and superior performance.

- Durability: Provides long-lasting results, reducing maintenance costs.

- Versatility: Ideal for a wide range of applications across multiple industries.

By sourcing from trusted suppliers like Honrel, businesses can access premium-grade white fused alumina that meets specific industrial requirements.