![]()

Fabricante y proveedor de alúmina fundida blanca: su fuente confiable de materiales abrasivos y refractarios de primera calidad

Al buscar un fabricante y proveedor confiable de alúmina blanca fundida, es esencial asociarse con empresas que no solo entreguen materiales de alta calidad, sino que también ofrezcan soluciones personalizadas para satisfacer necesidades industriales específicas. Alúmina fundida blanca (WFA) Es una materia prima fundamental que se utiliza en diversas industrias, principalmente en aplicaciones abrasivas y fabricación de refractarios. Este material versátil es conocido por su excepcional dureza, estabilidad química y alta pureza, lo que lo hace indispensable en numerosas aplicaciones.

Este artículo analiza en profundidad los factores clave que definen a un fabricante y proveedor de alúmina fundida blanca de primer nivel, explora las aplicaciones de la alúmina fundida blanca y ofrece orientación para seleccionar el proveedor adecuado para las necesidades de su negocio. Ya sea que trabaje en la industria metalúrgica, de la cerámica o de la construcción, comprender el papel de la alúmina fundida blanca en sus procesos le permitirá tomar decisiones más informadas al momento de adquirir este material fundamental.

Tabla de contenido

¿Qué es la alúmina blanca fundida (WFA)?

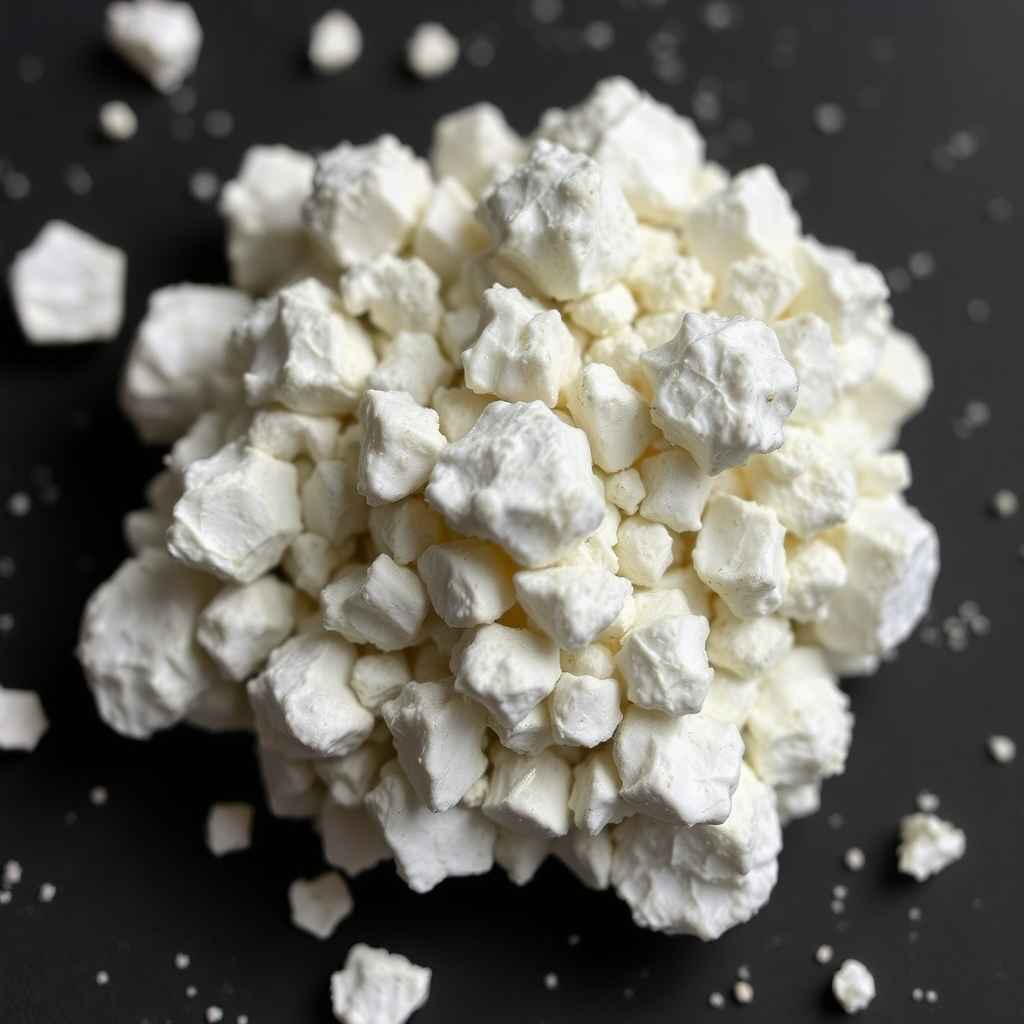

Alúmina fundida blanca El WFA es una forma de óxido de aluminio (Al₂O₃) de alta pureza que se produce fundiendo alúmina de alta calidad en un horno de arco eléctrico. El resultado es un material blanco y cristalino que es extremadamente duro y abrasivo. El proceso de fusión implica calentar bauxita o mezclas de bauxita y alúmina a temperaturas superiores a los 2000 °C, lo que garantiza que el producto final tenga una estructura consistente y de alta calidad.

La dureza, la alta pureza y la excelente estabilidad química del WFA lo convierten en un material ideal para diversas aplicaciones. Tiene una amplia gama de usos, desde abrasivos para esmerilado y pulido hasta refractarios y producción de cerámica. Se utiliza en diversas industrias, incluidas la automotriz, la aeroespacial, la construcción e incluso la electrónica.

Propiedades clave de la alúmina fundida blanca

1. Dureza:El WFA ocupa un lugar alto en la escala de dureza de Mohs, generalmente alrededor de 9, lo que lo hace muy eficaz para aplicaciones abrasivas. Esta propiedad es particularmente ventajosa en procesos de esmerilado, corte y pulido.

2. Alta pureza:La alúmina fundida blanca contiene generalmente más del 99 % de alúmina (Al₂O₃), lo que garantiza que no contiene impurezas. Esta pureza es vital para un rendimiento constante en aplicaciones de alta precisión.

3. Inercia química:El WFA es resistente a entornos ácidos y básicos, lo que lo hace ideal para su uso en condiciones químicas adversas. Esta propiedad amplía su utilidad en industrias como la producción de acero y materiales refractarios.

4. Estabilidad térmica:El material puede soportar temperaturas extremadamente altas, lo que lo hace adecuado para su uso en aplicaciones que implican tensiones térmicas, como en hornos o estufas.

5. Bajo desgaste abrasivo:La dureza y pureza de la alúmina blanca fundida contribuyen a su baja tasa de desgaste, lo que garantiza la longevidad y reduce la necesidad de reemplazo frecuente de material en aplicaciones industriales.

Tabla de análisis: Propiedades clave de la alúmina fundida blanca

| Propiedad | Valor | Solicitud |

|---|---|---|

| Dureza | 9 en la escala de Mohs | Abrasivos, muelas abrasivas |

| Pureza | 99% y más | Refractarios, Cerámica |

| Punto de fusión | 2050 °C | Aplicaciones de alta temperatura |

| Estabilidad química | Alto | Recubrimientos resistentes a la corrosión |

| Forma del grano | Angular/Afilado | Rectificado de precisión |

Aplicaciones de la alúmina fundida blanca

La alúmina fundida blanca se utiliza en diversas industrias, cada una de las cuales se beneficia de sus características únicas. Algunas de las principales aplicaciones incluyen:

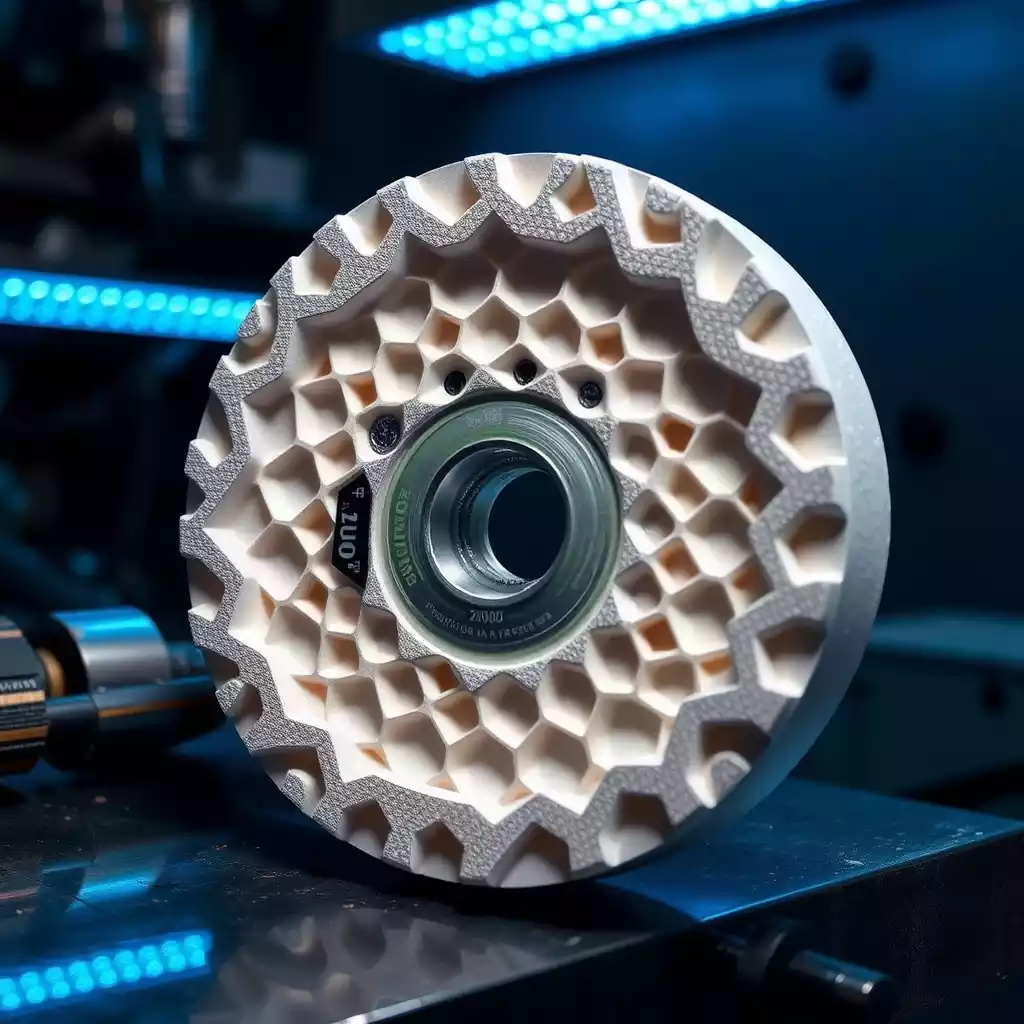

1. Abrasivos Industria

En el sector de los abrasivos, el WFA se utiliza principalmente para la fabricación de muelas abrasivas, papeles de lija y productos de pulido. Su extrema dureza lo hace eficaz para eliminar material rápidamente manteniendo un acabado fino. Los abrasivos fabricados con WFA se utilizan para lijar metales, piedra, cerámica y otros materiales duros.

2. Refractarios y Cerámicas

Como material refractario, la alúmina fundida blanca se utiliza en hornos, estufas y otros entornos de alta temperatura. Su capacidad para soportar calor extremo la convierte en un componente vital en industrias que requieren materiales que puedan mantener su integridad estructural en condiciones intensas. Además, se utiliza en la producción de productos cerámicos, incluidos azulejos, artículos sanitarios y cerámica industrial.

3. Catalizadores y producción de baterías

En los procesos químicos avanzados, el WFA se utiliza a veces como material de soporte en los procesos catalíticos. También desempeña un papel en la fabricación de componentes de baterías, en particular en baterías recargables de iones de litio y otros tipos de baterías.

4. Pulido y recubrimientos

La naturaleza fina y suave de la alúmina fundida blanca la convierte en un material popular para pulir metales, piedras y vidrio. También se utiliza en diversos revestimientos para mejorar la dureza del material y la resistencia a la corrosión.

5. Industria electrónica

Con sus excelentes propiedades de aislamiento, la alúmina fundida blanca se utiliza en la industria electrónica para recubrimientos aislantes y otros componentes que necesitan soportar alto voltaje o temperaturas extremas.

Tabla de análisis: principales industrias que utilizan alúmina fundida blanca

| Industria | Uso principal | Beneficios |

|---|---|---|

| Abrasivos | Papeles de lija, pulido | Rectificado de precisión, acabado de superficies |

| Refractarios | Revestimientos de hornos, revestimiento de hornos | Estabilidad a altas temperaturas |

| Electrónica | Recubrimientos aislantes | Aislamiento eléctrico |

| Cerámica | Azulejos, Sanitarios | Durabilidad, resistencia al calor. |

El papel de un fabricante y proveedor de alúmina fundida blanca

Elegir el fabricante y proveedor de alúmina fundida blanca adecuado es crucial para las industrias que dependen de este material para sus necesidades de producción. Un proveedor confiable garantiza la calidad, la consistencia y la entrega oportuna de este material esencial. Además, un buen fabricante puede ofrecer soporte técnico, tamaños personalizados y cantidades al por mayor, lo que puede ayudar a agilizar los procesos de producción y reducir los costos generales.

1. Alcance y distribución global

Los principales fabricantes y proveedores de alúmina fundida blanca operan a escala mundial y atienden a industrias de Europa, América, Corea del Sur, Japón, Rusia, Irán y otros lugares. Estas empresas comprenden las demandas únicas de cada mercado y pueden adaptar sus productos para cumplir con los estándares de la industria local.

Por ejemplo, los proveedores de Europa podrían proporcionar alúmina fundida blanca que cumpla con las estrictas regulaciones europeas para materiales refractarios, mientras que los proveedores de Corea del Sur podrían centrarse en abrasivos especializados adecuados para la fabricación de productos electrónicos.

2. Soluciones personalizadas

Los fabricantes de alúmina fundida blanca suelen ofrecer soluciones personalizadas que permiten a los clientes especificar el tamaño del grano, la forma y la pureza del material. Esta personalización es esencial para industrias como la de abrasivos y refractarios, donde la precisión y la consistencia son fundamentales.

3. Control de Calidad y Certificación

Un fabricante de confianza garantiza que su alúmina fundida blanca se produce bajo estrictas medidas de control de calidad. Las certificaciones como la ISO 9001 y otras normas específicas de la industria se utilizan a menudo para demostrar el compromiso del fabricante con la calidad. Estas certificaciones también garantizan a los clientes que están recibiendo un producto confiable y consistente.

4. Investigación y desarrollo

Los principales fabricantes invierten en investigación y desarrollo (I+D) para mejorar continuamente la calidad de la alúmina blanca fundida y adaptarla a nuevas aplicaciones industriales. La innovación en el proceso de producción puede dar como resultado un producto más eficiente, rentable o respetuoso con el medio ambiente.

Cómo elegir el proveedor adecuado de alúmina fundida blanca

A la hora de seleccionar un proveedor de alúmina fundida blanca, se deben tener en cuenta varios factores para garantizar una relación duradera y fiable. Estos factores incluyen:

1. Calidad del producto

Es fundamental elegir un proveedor conocido por la alta calidad de su alúmina fundida blanca. El material debe cumplir con los estándares industriales necesarios en cuanto a pureza, dureza y consistencia.

2. Confiabilidad de la cadena de suministro

La capacidad del proveedor para entregar la cantidad requerida a tiempo es crucial para mantener los cronogramas de producción. Los proveedores con una sólida red de distribución global pueden ayudar a mitigar los retrasos y garantizar que las empresas reciban sus materiales sin interrupciones.

3. Atención y servicio al cliente

Un buen proveedor ofrece un excelente servicio al cliente, que incluye soporte técnico, seguimiento de entregas y asistencia con la selección de materiales. Esto ayuda a las empresas a tomar decisiones informadas y a abordar cualquier desafío que pueda surgir durante el proceso de producción.

4. Competitividad de precios

Si bien el precio no debería ser el único factor decisivo, sin duda es un factor importante. Compare los precios de diferentes proveedores para asegurarse de obtener la mejor relación calidad-precio. Sin embargo, asegúrese siempre de que la calidad del producto justifique el costo.

Ventajas de trabajar con un fabricante y proveedor líder de alúmina blanca fundida

Trabajar con un fabricante y proveedor de alúmina blanca fundida de buena reputación proporciona numerosos beneficios a las industrias que dependen de este material para aplicaciones críticas:

1. Suministro y calidad constantes

Los principales fabricantes y proveedores tienen un historial comprobado de proporcionar alúmina blanca fundida de alta calidad de manera constante. Esta confiabilidad ayuda a las empresas a mantener la eficiencia de producción sin preocuparse por la escasez de material o problemas de calidad.

2. Soluciones personalizadas

Los fabricantes pueden adaptar la alúmina fundida blanca para satisfacer las necesidades específicas de su aplicación, lo que garantiza que las propiedades del material estén optimizadas para su proceso de producción. Este nivel de personalización puede proporcionar una ventaja competitiva en su industria.

3. Acceso a conocimientos técnicos

Muchos proveedores de alúmina fundida blanca ofrecen asesoramiento especializado sobre cómo utilizar el material de manera eficaz. Este soporte técnico puede ayudar a mejorar su proceso de fabricación y reducir los costos al garantizar que está utilizando el tipo de alúmina adecuado para sus necesidades.

4. Disponibilidad global

Un proveedor global puede obtener alúmina fundida blanca de múltiples ubicaciones, lo que garantiza que el material esté disponible sin importar dónde se encuentre su empresa. Esto puede ser especialmente beneficioso para las empresas con operaciones en varios países.

Conclusión

En conclusión, la alúmina fundida blanca es un material versátil y de alto rendimiento que se utiliza en una amplia gama de industrias, desde abrasivos hasta refractarios y electrónica. Como fabricante y proveedor de este valioso material, materia prima química, Honrel se compromete a proporcionar alúmina fundida blanca de la más alta calidad a clientes de todo el mundo. Con un enfoque en la calidad, la confiabilidad y la atención al cliente, nos aseguramos de que nuestros clientes reciban los mejores materiales para mejorar sus procesos de producción.

A medida que la demanda de alúmina fundida blanca continúa creciendo en diferentes sectores, es importante elegir un proveedor que comprenda las necesidades únicas de su industria y pueda ofrecer productos que cumplan con los estándares más altos. Al asociarse con un fabricante confiable, puede garantizar el éxito y la eficiencia de sus operaciones.

Sección de preguntas frecuentes:

¿La alúmina fundida blanca está disponible a nivel mundial? Sí, muchos proveedores, incluido Honrel, proporcionan alúmina blanca fundida a clientes de todo el mundo, lo que garantiza la disponibilidad en diferentes mercados.

¿Para qué se utiliza la alúmina blanca fundida? La alúmina blanca fundida se utiliza en abrasivos, refractarios, cerámicas y diversas aplicaciones químicas y de alta temperatura debido a su dureza y alta pureza.

¿Qué hace que la alúmina fundida blanca sea diferente de otras alúminas? La alúmina fundida blanca se produce con niveles de pureza más altos y es conocida por su estructura de grano uniforme, lo que la hace particularmente adecuada para aplicaciones de precisión.

¿La alúmina blanca fundida es respetuosa con el medio ambiente? Si bien la alúmina blanca fundida se produce utilizando hornos eléctricos de alta temperatura, su impacto ambiental es relativamente bajo en comparación con otros materiales industriales.

¿Cómo elijo el proveedor adecuado para alúmina fundida blanca? Elija un proveedor que ofrezca productos de alta calidad, entrega oportuna, precios competitivos y excelente atención al cliente.

¿Se puede personalizar la alúmina fundida blanca? Sí, Honrel Los fabricantes pueden personalizar el tamaño del grano, la forma y la pureza de la alúmina fundida blanca para satisfacer las necesidades específicas de diferentes industrias.

¿Qué industrias se benefician de la alúmina blanca fundida? Industrias como la de abrasivos, refractarios, automotriz, aeroespacial y electrónica se benefician de las propiedades de la alúmina blanca fundida.

¿Qué certificaciones debe tener un proveedor confiable de alúmina blanca fundida? Un proveedor confiable debe tener certificaciones como ISO 9001 para garantizar una calidad constante del producto y el cumplimiento de los estándares de la industria.