![]()

루테늄 촉매란 무엇입니까?

루테늄 촉매 소개

화학 원료의 선도적인 글로벌 공급업체인 Honrel에서는 고성능 제품 제공을 전문으로 합니다. 루테늄 촉매 산업용 애플리케이션에 맞게 맞춤 제작되었습니다. 활성탄에 루테늄 촉매(CAS No. 7440-18-8)는 수소화, 산화 및 에너지 변환 공정의 효율성을 최적화하도록 설계되었습니다. 유럽, 미국, 아시아 및 중동 전역의 공장 및 대량 구매자를 위해 설계된 당사의 촉매는 최첨단 기술과 비용 효율적인 솔루션을 결합합니다.

목차

1. 루테늄 촉매란 무엇입니까?

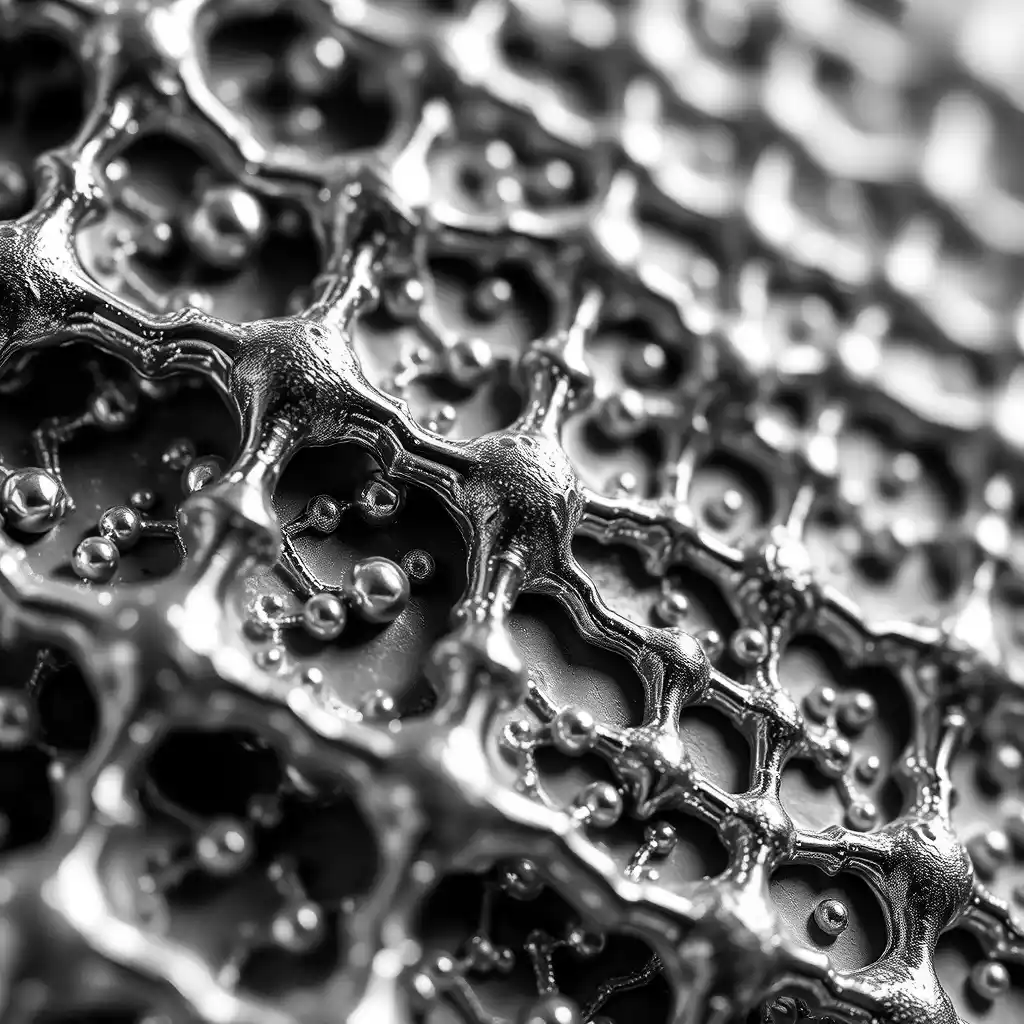

루테늄 촉매는 화학 가속기입니다. 루테늄 금속 다공성 지지체 재료에 분산되어 있습니다 활성탄이러한 조합은 산업 공정에서 반응 속도를 높이고, 에너지 소비를 줄이며, 제품 수율을 향상시킵니다.

1.1 왜 루테늄인가?

- 높은 활동성: 루테늄의 독특한 전자 배열은 효율적인 결합 파괴와 형성을 가능하게 합니다.

- 열 안정성: 최대 500°C의 온도에서 효과적으로 작동합니다.

- 부식 저항성: 산성이나 알칼리성 환경에 이상적입니다.

1.2 활성탄의 역할

활성탄(AC)은 다음과 같은 역할을 합니다. 고표면적 캐리어, 루테늄 나노입자 응집을 방지합니다. Honrel은 코코넛 껍질, 석탄, 나무, 이탄에서 AC를 제공하며 각각 특정 응용 분야에 최적화되어 있습니다.

2. Honrel의 루테늄 촉매 사양

우리의 루테늄 촉매 (등급: Ru 101, Ru 103, Ru 105, Ru 107, Ru 110)은 다양한 산업적 요구에 맞게 사용자 정의할 수 있습니다.

2.1 기술적 매개변수

| 재산 | 명세서 |

|---|---|

| 루테늄 함량 | 0.1% – 30% (비용 또는 성능 중심 애플리케이션에 맞게 조정 가능) |

| 캐리어 소재 | 코코넛 껍질, 석탄, 나무, 이탄 |

| 특정 표면적 | ≥930 m²/g (분말 AC); 750–1,320 m²/g (기둥형/과립형 AC) |

| 금속 표면적 | 85–105 m²/g(활성 사이트 접근성 보장) |

| 입자 크기 | 15–100 μm(분말); 0.8–4mm(기둥형); 4–12 메시(조각형/과립형) |

| 불순물 | ≤0.3% (Cu, Fe, Cr, Ni, Ag, Mg) – 안정적인 성능을 위한 최소한의 오염 물질 |

| 수분 함량 | 0.1%–65% (슬러리 또는 건조상 반응에 맞게 조정 가능) |

Honrel의 탐험 루테늄 촉매 제품 페이지

3. 루테늄 촉매의 산업적 응용

당사의 촉매는 다재다능함으로 인해 전 세계 산업계에서 신뢰를 받고 있습니다.

3.1 수소화 반응

- 제약품: 니트로 화합물의 선택적 수소화로 아민을 생성합니다(예: 파라세타몰 중간체).

- 식품 가공: 150°C에서 10% Ru/wood AC를 사용하여 식물성 오일의 트랜스지방 감소.

- 정밀화학: 5% Ru/코코넛 AC를 이용한 향수 및 염료 생산.

3.2 에너지 및 환경 솔루션

- 암모니아 합성: Ru/AC(20% 적재)는 50~100bar 압력에서 기존 Fe 촉매보다 성능이 우수합니다.

- 수소 생산: 600°C에서 효율적인 암모니아 분해를 통한 깨끗한 에너지 생산.

- CO₂ 전환: Ru-K/AC 시스템은 CO₂를 메탄(Sabatier 반응)으로 전환하여 탄소 포집을 돕습니다.

3.3 석유화학 정제

- 피셔-트롭쉬 합성: 10% Ru/석탄 AC를 사용하여 합성가스로부터 선형 알케인을 생산합니다.

- 탈황: 수소탈황(HDS)을 통해 디젤에서 유황 화합물을 제거합니다.

4. 왜 Honrel의 루테늄 촉매를 선택해야 합니까?

4.1 글로벌 시장을 위한 맞춤형

- 통신사 유연성: 소형 분자용 코코넛 껍질 AC(높은 미세기공), 석유화학제품용 석탄 AC(중기공).

- 입자 크기 최적화: 15~100 μm 분말이나 4~12 메시 과립을 귀하의 반응기 필터 시스템에 맞춰 사용하세요.

- Ru 로딩 제어: 0.1%(저비용 배치 공정)부터 30%(고활성 연속 반응기)까지.

4.2 품질 보증

- 청정: ≤0.3% 불순물은 촉매 중독이 발생하지 않음을 보장합니다.

- 내구성: 입자 강도 ≥90%로 유동화층에서의 마모를 최소화합니다.

- 규정 준수: 글로벌 수출을 위한 REACH, OSHA, ISO 표준을 충족합니다.

4.3 비용 및 시간 효율성

- 대량 할인: 유럽, 일본, 러시아, 이란의 공장에 경쟁력 있는 가격을 제공합니다.

- 원스톱 공급: 루테늄 촉매와 우리의 쌍 귀금속 또는 희토류 제품 간소화된 조달을 위해.

5. 올바른 루테늄 촉매를 선택하는 방법

5.1 반응에 맞는 캐리어 소재 선택

- 코코넛 껍질 AC: 수소 저장에 가장 적합(미세 다공성 구조).

- 석탄 기반 AC: 중질 탄화수소 처리에 이상적입니다.

- 목재 에어컨: VOC 산화에 비용 효율적입니다.

5.2 반응기 유형 고려

- 고정층 반응기: 낮은 압력 강하를 위해 원주형 AC(0.8~4mm)를 사용합니다.

- 슬러리 반응기: 최대 표면 접촉을 위해 분말 AC(30 μm)를 선택하세요.

5.3 무료 상담 요청

Honrel의 기술팀이 제공합니다 무료 애플리케이션 분석 최적의 Ru 등급과 캐리어를 추천해드립니다.

6. 루테늄 촉매에 대한 FAQ

Q1: 대량 주문의 리드타임은 얼마인가요?

답변: 대부분 주문은 7~14일 이내에 배송되며, 긴급한 경우에는 긴급 배송 옵션도 제공됩니다.

질문 2: Honrel은 불순물 한도를 맞춤 설정할 수 있나요?

A: Yes – we adjust leaching processes to meet specific purity requirements (e.g., <0.1% Fe).

Q3: 재생 서비스를 제공하시나요?

A: 네! 우리는 산 세척이나 열처리를 통해 소모된 촉매에서 90% 이상의 Ru를 회수합니다.

7. Honrel과 협력하세요 – 글로벌 화학 원료 공급업체

15개국 이상의 고객을 보유한 Honrel은 화학 산업에서 신뢰성의 대명사입니다. 촉매 원료 카테고리 제공:

- 루테늄, 팔라듐 및 백금 촉매

- 제올라이트, 분자체 및 효소 촉매

- 틈새 시장을 위한 맞춤형 블렌드

8. 결론

루테늄 촉매는 현대 산업에 없어서는 안 될 요소이며, Honrel은 성능, 비용, 확장성을 균형 있게 조절하는 솔루션을 제공합니다. 독일의 바이오연료 정제 공장이든, 한국의 제약 합성 화학 공장이든, 활성탄에 루테늄 촉매는 성공을 위해 설계되었습니다.

프로세스를 최적화할 준비가 되셨나요?

오늘 Honrel에 연락하세요 견적이나 기술 상담을 원하시면.