![]()

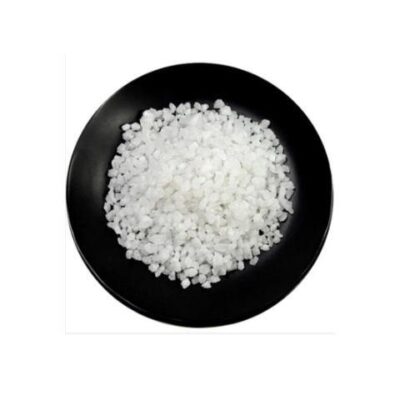

Alúmina tabular

Tabular Alumina (TA) is pure α-alumina resulting from intensive sintering at temperatures exceeding 1,800 °C, without sintering additives. Low temperature expansion and high heat resistance can be explained by the micro structure specifics: low effective porosity and large sizes of crystals with closed spherical pores resulting from intensive sintering. Tabular alumina has exceptionally high refractory properties, mechanical strength, wear resistance, chemical purity, dielectric properties, and excellent corrosive resistance in acid and alkaline environments.

Aplicaciones:

Materiales refractarios

Tabular alumina is one of the most commonly used oxides in refractory material production, such as different types of concrete, brick, monolithic products, insulation materials and other products.

Cerámica

Thermostability, electrical resistance, strength, high melting point and resistance against chemicals enable a broad field of application of tabular alumina in the ceramics industry.

Resinas epoxi

Adding alumina to epoxy resins enhances the mechanical properties (e.g. strength and abrasion resistance), thermal conductivity and dielectric properties of materials.

Oil industry

The excellent properties of tabular alumina, such as chemical and thermostability, enable its use in processes that run under exacting conditions.

Foundry industry

The characteristics of low-alkaline tabular alumina , especially the low impurity content, make it interesting for use in the foundry industry, especially in modular casting.

Alúmina tabular

True Gravity: ≥3.50 g /cm3

Mosh Hardness: 9

Color: White

Loss on Ignition(LOI): ≤1.5%

Porosity: ≤5%

Coefficient Expansion Index(0-1600 ℃ ): 7-9

Especificación:

| Tamaño de partícula | Chemical composition | Physical properties | Bulk density | |||||

| AI2O3% | SiO2% | Fe2O3% | Na2O% | Bulk density

(g/cm3) |

Water absorption | Apparent porosity | g/cm3 | |

| ≥ | ≤ | ≤ | ≤ | ≥ | ≤ | ≤ | ≥ | |

| 0-1 mm 0-0-5mm l-2mm l-3mm 3-5mm 5-8mm 5-10mm | 99.5 min | 0.06 max | 0.02 max | 0.25 max | 3.5 | 1.5 | 4max | 3.6 |

| 200#-0 320#-0

325# |

99.3 min | 0.06 max | 0.04 max | 0.25 max | 3.5 | 2 | 4max | 3.5 |

Embalaje:

25kg/woven bag, 1MT or 1.2MT or 1.25MT/jumbo bag on pallet

40 x 25kg/woven bags into one jumbo bag

20-25MT/20FCL